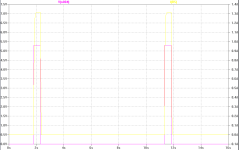

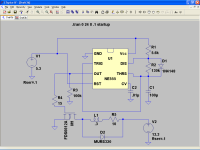

Mechanical fuel pumps usually work well when new . I am referring to those on Kohler , Briggs , and Kawasaki engines , including the pulse vacuum type. However all my Kohler engines are old : 1971 K321 (14Hp) ; and 1995 CV15.5Hp . I am not a fan of the new plastic fuel pumps , which do not last as long as the originals. A leaking diaphragm puts fuel in the oil sump . Which brings me to electric fuel pumps . I have been using them on engines since 1970. I have one on my 1.9L Bobcat that has been running strong since before 2005. The problem comes when trying to use one on the CV15.5Hp (single cylinder) . The pressure is too high even at 4psi ; the flow is also too high at 28 to 30 gal per hour. That is enough fuel o run a 300Hp V8 at wide open throttle ! Various techniques have been used in the past : split the fuel pump output with a T-fitting , run a return line to the gas tank , add a fuel pressure regulator to the carb at .5psi . The regulator alone is $55. The technique I am showing today is a Spice model of an electronic control. The On time is controlled by R1xC1 ; Off time by R2xC1; nominally set to .5sec On , 10sec Off. Tolerance of parts must be considered: 20% on C1 can be offset in the opposite direction with each resistor . Best to measure the C1 first to be within 5% overall timing. All components are available at Digikey. C1= Rubycon 100uF , 35V , 20%. U1 = Ti LMC555 CMOS Timer. M1 Mosfet = Fairchild /Onsemi FDP8896 (obsolete but in stock). V1 at 5.3V is the output of LM317 regulator in a TO220 package. D2 is a 3A 200V Fast recovery diode across the fuel pump leads. L1 and R5 represent typical values for a 1.2A pump.

V2 at 13.3V is the switched battery voltage with charging. Estimated flow is 2.8 to 3.0 gal per hour; more like 30Hp.

Build notes : add a .1uF capacitor right at pin 8 of U1. U1 and the gate of M1 are static sensitive. Wear a grounded wrist strap and use a grounded tip iron. Follow the layout notes in the datasheet . On time can be reduced to .25sec by reducing R1. Off time can be extended to 20 sec by increasing R2.

Pumps available on Amazon : HEP02A and Megaflint are available at reasonable cost . However the reviews indicate quality problems on some pumps. To give the pumps the best chance at survival , mount them to the tractor frame away from engine vibration , with the output aimed upward at 30 to 90 degrees (prevents air bubbles). The pump inlet should be no higher than 12" above the fuel level , and still be able to prime without burning out the pump. I will also be adding a momentary grounding switch in parallel with M1 , to pump the fuel bowl full right before starting .

V2 at 13.3V is the switched battery voltage with charging. Estimated flow is 2.8 to 3.0 gal per hour; more like 30Hp.

Build notes : add a .1uF capacitor right at pin 8 of U1. U1 and the gate of M1 are static sensitive. Wear a grounded wrist strap and use a grounded tip iron. Follow the layout notes in the datasheet . On time can be reduced to .25sec by reducing R1. Off time can be extended to 20 sec by increasing R2.

Pumps available on Amazon : HEP02A and Megaflint are available at reasonable cost . However the reviews indicate quality problems on some pumps. To give the pumps the best chance at survival , mount them to the tractor frame away from engine vibration , with the output aimed upward at 30 to 90 degrees (prevents air bubbles). The pump inlet should be no higher than 12" above the fuel level , and still be able to prime without burning out the pump. I will also be adding a momentary grounding switch in parallel with M1 , to pump the fuel bowl full right before starting .