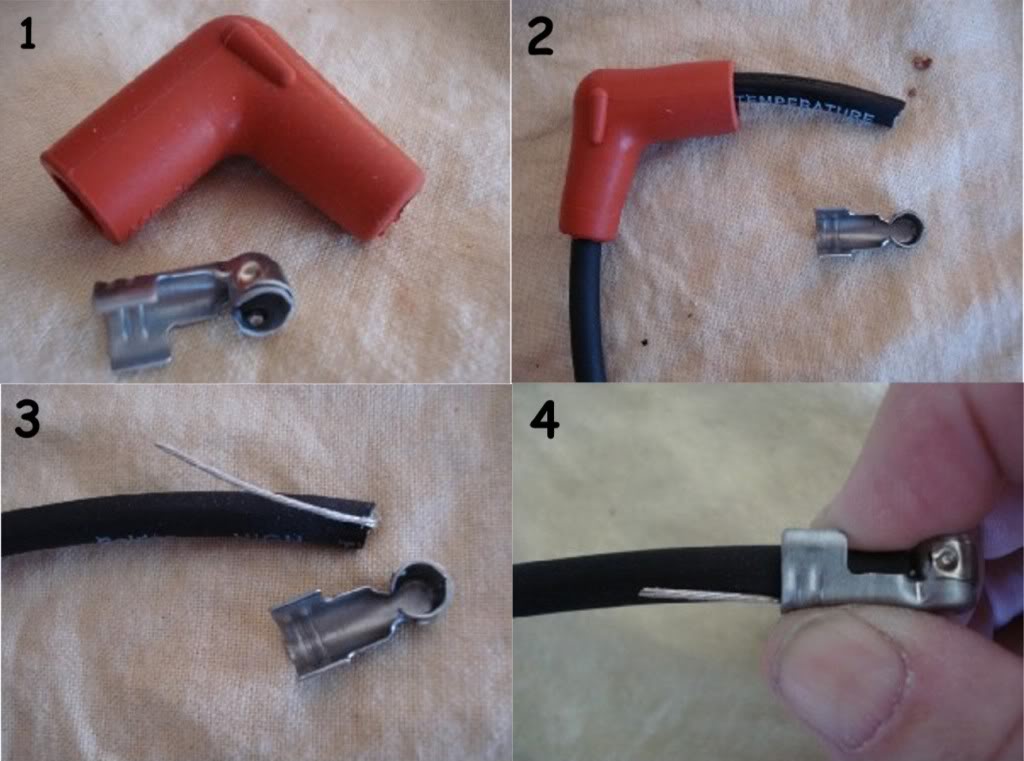

I'm planning on replacing the spark plug wires on my 8N. I bought a set from YT that have the ends clips like this.

Most of the instructions I've seen have ends more like this:

Instructions for the 2nd type show the core of the wire long enough sticking out of the SP wire to fold over and crimp the end around the outer and jacket together.

With the type of end I have, is it done any differently? The wires currently on the tractor look to have a short length of core that attaches to the end clip somehow - I can't see for sure, but it doesn't look bent over

What's the most secure way to make this connection?

Most of the instructions I've seen have ends more like this:

Instructions for the 2nd type show the core of the wire long enough sticking out of the SP wire to fold over and crimp the end around the outer and jacket together.

With the type of end I have, is it done any differently? The wires currently on the tractor look to have a short length of core that attaches to the end clip somehow - I can't see for sure, but it doesn't look bent over

What's the most secure way to make this connection?