Hi, I recently joined this forum because it became apparent to me quickly that you were the gurus I seek. I'm new, I'm not afraid, but I do have a budget.

656 Gas Hydro has had a misfire and I finally was able to get into it for what I had hoped would just be a valve adjustment. #3 had a lot of oil around the manifold and showed fouled plugs. The valves were in desperate need of adjusting, but still I lost compression in #4 out through the manifold after setting the proper lash. I pulled the head.

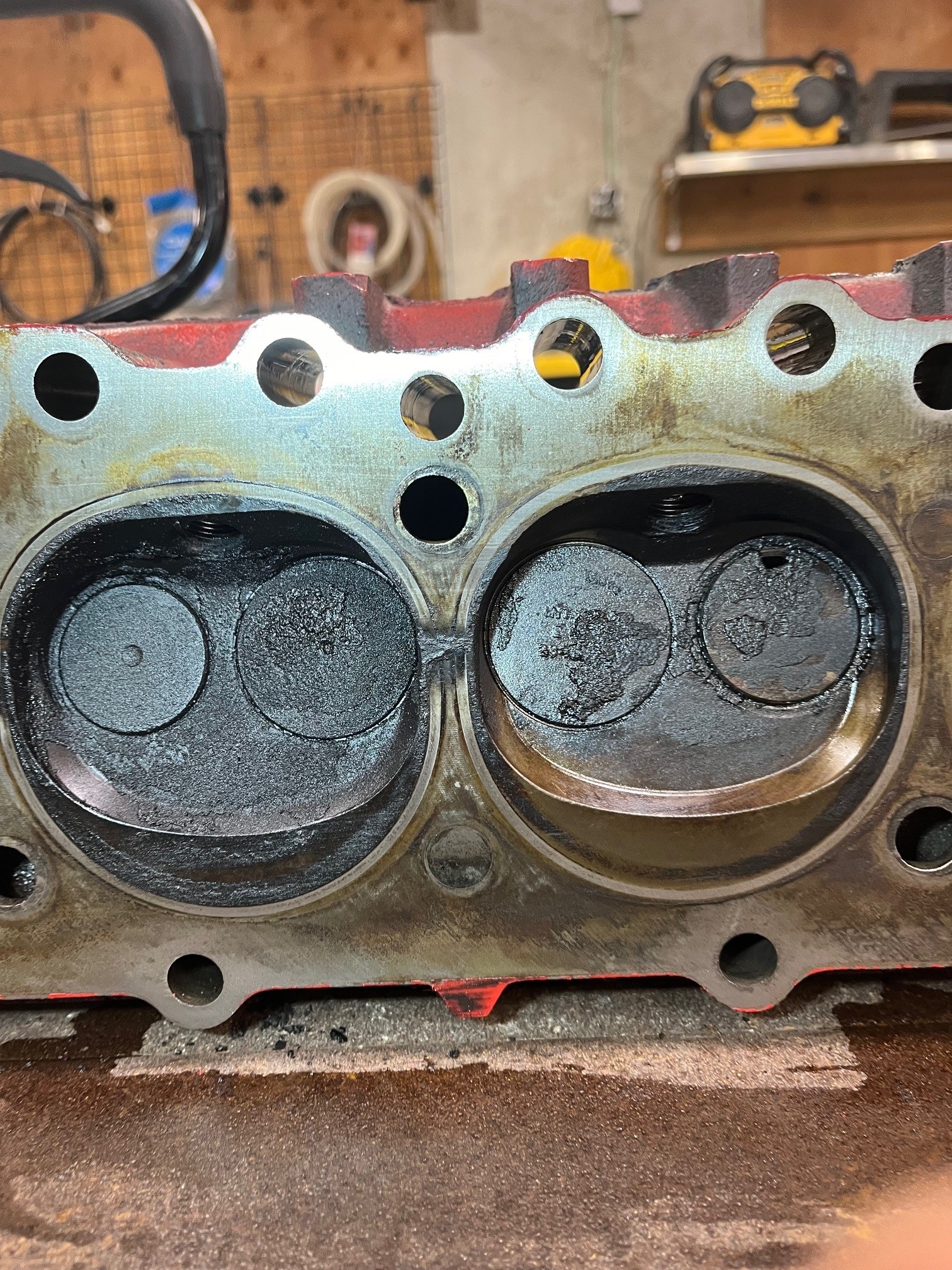

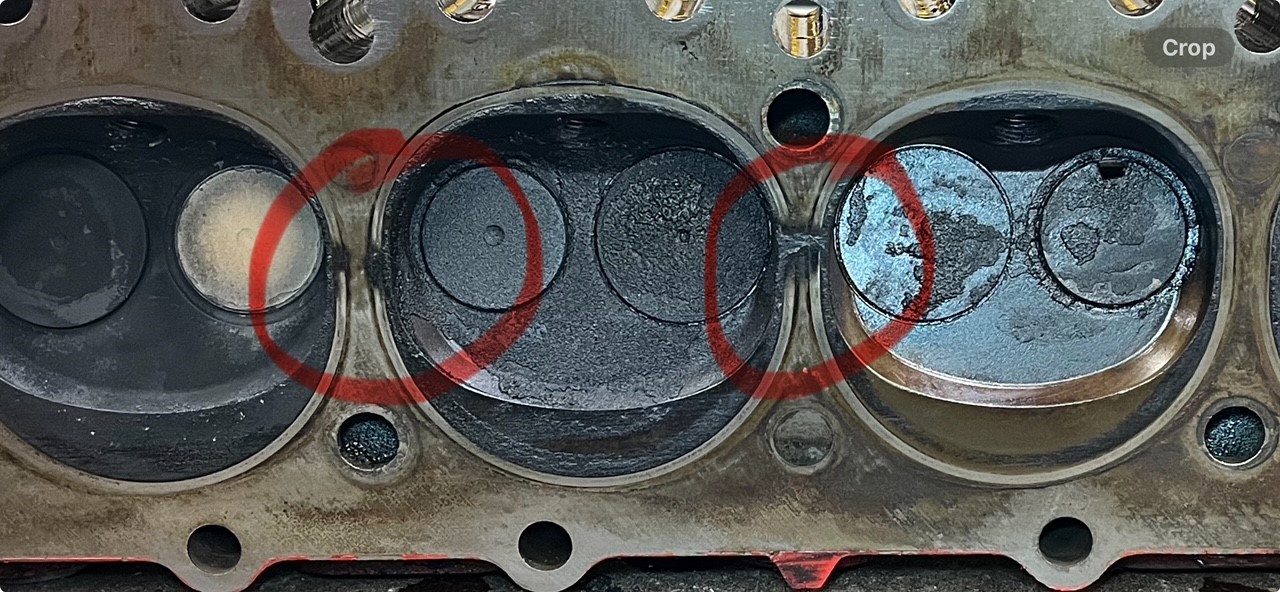

The Head gasket was blown between 3 & 4 and had wear showing between 2 & 3. There's a hole in a valve in #4 as well and there is a lot of built up deposits. I plan to replace the entire valve train and bring the head into a machine shop to true it. I'd like to avoid anything more than cleaning up the deposits from bottom end if possible.

After some reading, I've come to understand that what I'm seeing is possible after overheating and I did that once a year prior after unknowingly losing my fan belt while plowing. Since this machine doesn't see too much heavy work, I didn't really notice a performance issue until late 2023.

What are your thoughts? I'm curious as to your suspicion for the cause of this issue and if you think I can avoid pulling the block apart and rebuilding it completely. What are some key metrics to make that call accurately? TIA

656 Gas Hydro has had a misfire and I finally was able to get into it for what I had hoped would just be a valve adjustment. #3 had a lot of oil around the manifold and showed fouled plugs. The valves were in desperate need of adjusting, but still I lost compression in #4 out through the manifold after setting the proper lash. I pulled the head.

The Head gasket was blown between 3 & 4 and had wear showing between 2 & 3. There's a hole in a valve in #4 as well and there is a lot of built up deposits. I plan to replace the entire valve train and bring the head into a machine shop to true it. I'd like to avoid anything more than cleaning up the deposits from bottom end if possible.

After some reading, I've come to understand that what I'm seeing is possible after overheating and I did that once a year prior after unknowingly losing my fan belt while plowing. Since this machine doesn't see too much heavy work, I didn't really notice a performance issue until late 2023.

What are your thoughts? I'm curious as to your suspicion for the cause of this issue and if you think I can avoid pulling the block apart and rebuilding it completely. What are some key metrics to make that call accurately? TIA