About six years ago I purchased a gantry crane, Strongway hoist and Strongway trolley from Northern tool. It has proven to be one of the most useful

tools in my shop. A couple of days ago I was moving the crane from one tractor to another when the control unit for the trolley caught on something on

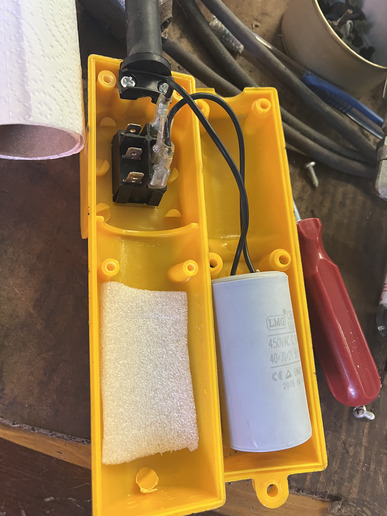

tractor one and pulled the unit right off the cord. I had a control unit on my floor and a cord with three dangling wires. I took the control unit apart to

see if the wires could be easily re-connected. Turns out there is a capacitor or something in the handle. I'm reluctant to just start re-connecting wires

as I'm afraid of burning out the capacitor (or whatever it is). I am diligent about keeping all my user manuals but can't find this one. I called Northern

Tool but they no longer carry this unit and cannot provide me with a user manual. The unit is made in China and I've had no luck finding a user manual

on-line. I'm putting this message up to see if any readers have one of these trolleys, would be willing to take the cover off their control unit, take a

picture showing how the wires are attached (which colors go where) and e-mail it to me. I would be grateful.

tools in my shop. A couple of days ago I was moving the crane from one tractor to another when the control unit for the trolley caught on something on

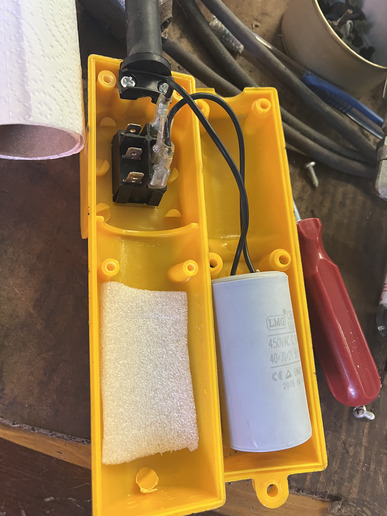

tractor one and pulled the unit right off the cord. I had a control unit on my floor and a cord with three dangling wires. I took the control unit apart to

see if the wires could be easily re-connected. Turns out there is a capacitor or something in the handle. I'm reluctant to just start re-connecting wires

as I'm afraid of burning out the capacitor (or whatever it is). I am diligent about keeping all my user manuals but can't find this one. I called Northern

Tool but they no longer carry this unit and cannot provide me with a user manual. The unit is made in China and I've had no luck finding a user manual

on-line. I'm putting this message up to see if any readers have one of these trolleys, would be willing to take the cover off their control unit, take a

picture showing how the wires are attached (which colors go where) and e-mail it to me. I would be grateful.