Hi All,

I'm changing the fluid on my "new to me" MF32 Loader. Whoever changed the fluid last appears to have used silicone in place of O-ring (Part # 359111X1) which seals the filter can to the resivoir.

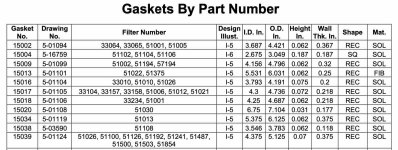

I saw another post here on YT that said it's a 4-7/8" ID X 1/8" O-Ring.

Would it be ok to utilize some Permatex Ultra black (sparingly) to get this seal made, so that I don't have to go out hunting for an O-Ring that will fit this particular application?

Or would these O-Rings work (see link below) (I don't know much about O-Rings, so though I'd ask some more knowledgeable folks here). https://www.grainger.com/product/O-Ring-249-1KLH7

I'm changing the fluid on my "new to me" MF32 Loader. Whoever changed the fluid last appears to have used silicone in place of O-ring (Part # 359111X1) which seals the filter can to the resivoir.

I saw another post here on YT that said it's a 4-7/8" ID X 1/8" O-Ring.

Would it be ok to utilize some Permatex Ultra black (sparingly) to get this seal made, so that I don't have to go out hunting for an O-Ring that will fit this particular application?

Or would these O-Rings work (see link below) (I don't know much about O-Rings, so though I'd ask some more knowledgeable folks here). https://www.grainger.com/product/O-Ring-249-1KLH7