jon f mn

Well-known Member

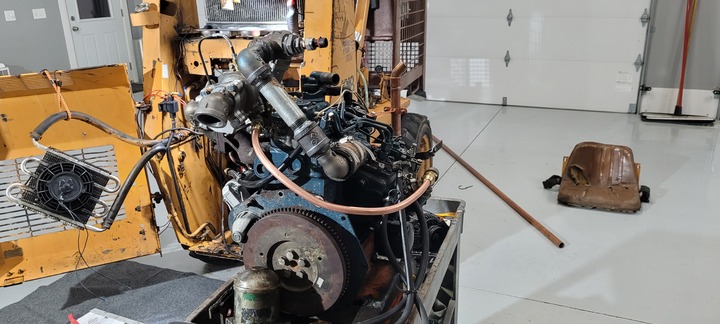

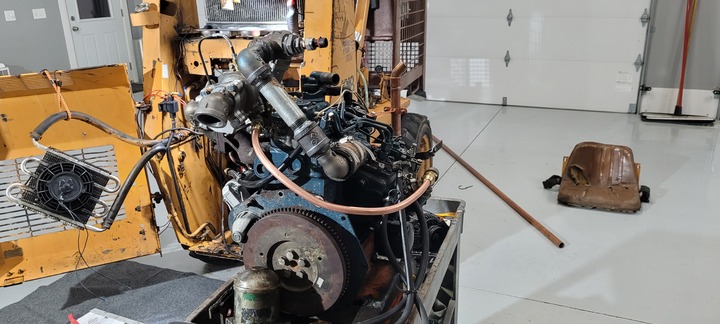

Finally got time to install the turbo on the little Kubota I put in my skidloader. Was a big job and harder than it looked. To start I couldn't just bolt the turbo to the manifold because there wasn't room, so I had to make this elbow setup.

The turbo to engine side was hard too as I couldn't find any light pipe that would turn sharp enough. And I didn't want to use plastic or rubber because it might get hot. So that was also pipe. To get things to fit right I had to start the. Threaded then welded those together.

St

The turbo came with a kit of plates that could be drilled and tapped fo fittings, but for a but 2 there wasn't room for that, so we had to cut the threaded part off the fittings and weld them on.

The only one we had issues with was the oil return, that one had pin holes in the weld. We had a terrible time getting those closed up. Must have ground and welded the one side 6 or 8 times.

Also did some changes to the water inlet on the motor. The angle the pipe came out of the motor made it hard to keep the hoses off the belts. So I made up the copper pipe setup that wil hopefully resolve that issue.

I also added a gage set that monitors egt, boost pressure and oil temp. When it's all together it fits pretty well.

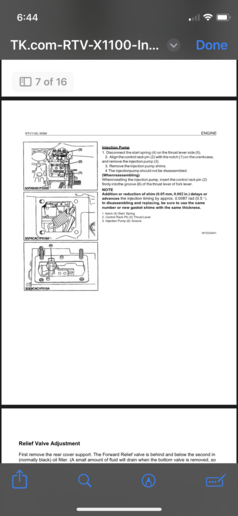

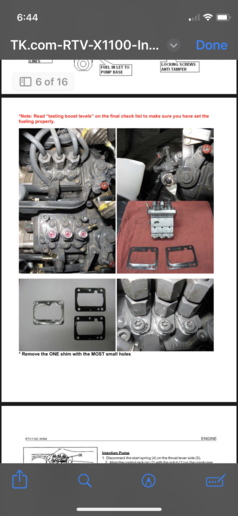

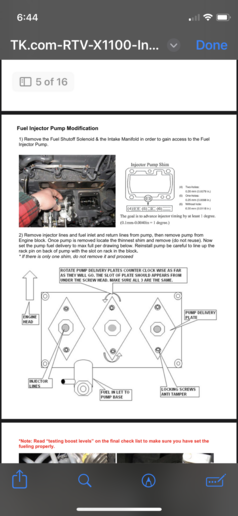

Has a lot more power now and make everything work better. Does smoke a lot, I'm thinking I might have to advance the timing a little. So far i havent found much info on how to do that. It does say something about shims, but not where thet are or if you add or take out.

Shows 7 psi of boost and exhaust temperatures have been as high as 1000 deg so far. I'm surprised at how much extra power it has with only that low boost pressure. I'll keep tweaking it a bit to get things set right.

The turbo to engine side was hard too as I couldn't find any light pipe that would turn sharp enough. And I didn't want to use plastic or rubber because it might get hot. So that was also pipe. To get things to fit right I had to start the. Threaded then welded those together.

St

The turbo came with a kit of plates that could be drilled and tapped fo fittings, but for a but 2 there wasn't room for that, so we had to cut the threaded part off the fittings and weld them on.

The only one we had issues with was the oil return, that one had pin holes in the weld. We had a terrible time getting those closed up. Must have ground and welded the one side 6 or 8 times.

Also did some changes to the water inlet on the motor. The angle the pipe came out of the motor made it hard to keep the hoses off the belts. So I made up the copper pipe setup that wil hopefully resolve that issue.

I also added a gage set that monitors egt, boost pressure and oil temp. When it's all together it fits pretty well.

Has a lot more power now and make everything work better. Does smoke a lot, I'm thinking I might have to advance the timing a little. So far i havent found much info on how to do that. It does say something about shims, but not where thet are or if you add or take out.

Shows 7 psi of boost and exhaust temperatures have been as high as 1000 deg so far. I'm surprised at how much extra power it has with only that low boost pressure. I'll keep tweaking it a bit to get things set right.