lastcowboy32

Well-known Member

OK, so, it's a 269 baler. My brother, who has baled probably a million bales, ran it yesterday, and he made some tweaks; but we're still looking for root cause...and we're thinking twin discs are loose and not holding the twine. This is why. Please critique.

Thanks.

Here are the symptoms:

Baler makes great knots with plastic twine. I just don't run it, because the plastic burns on the thrower belt. (Although, I'm making shorter bales now, I could revisit...)

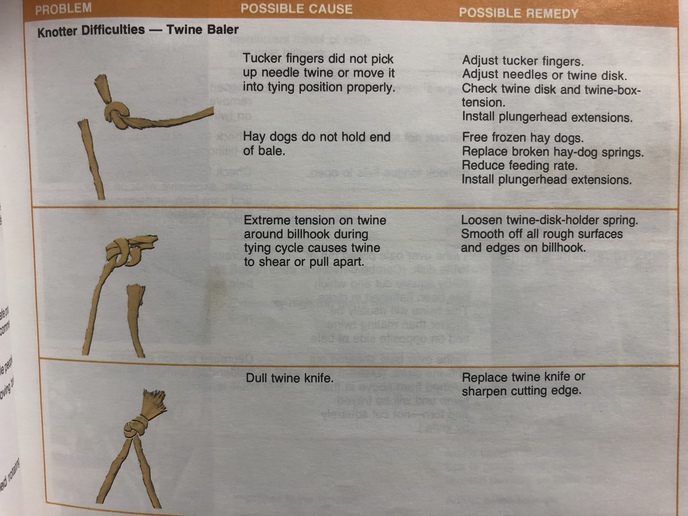

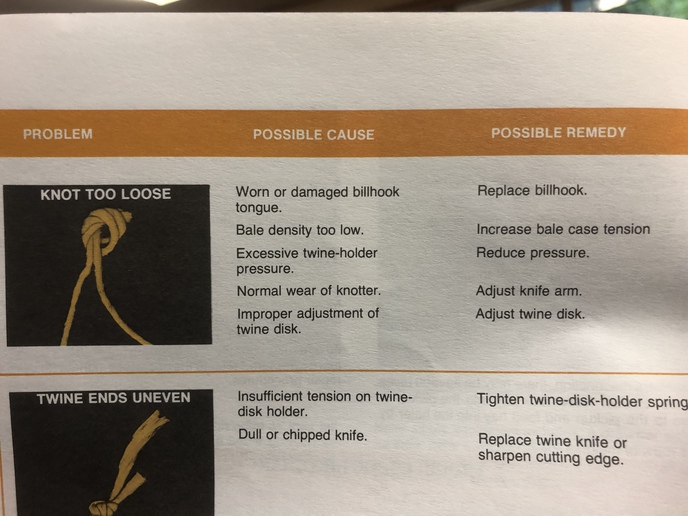

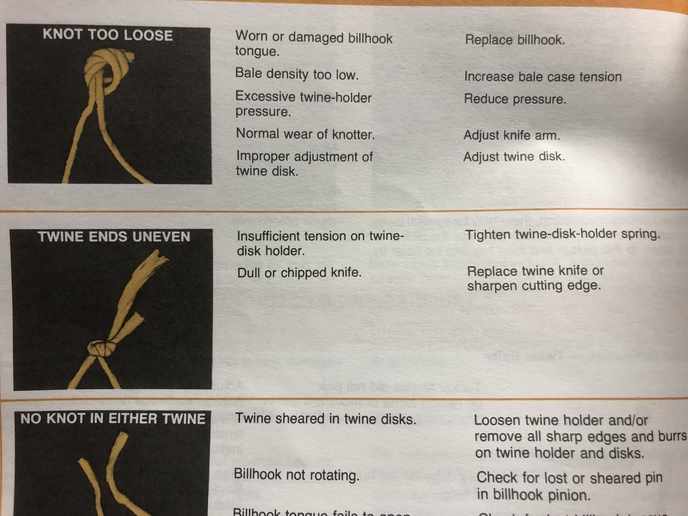

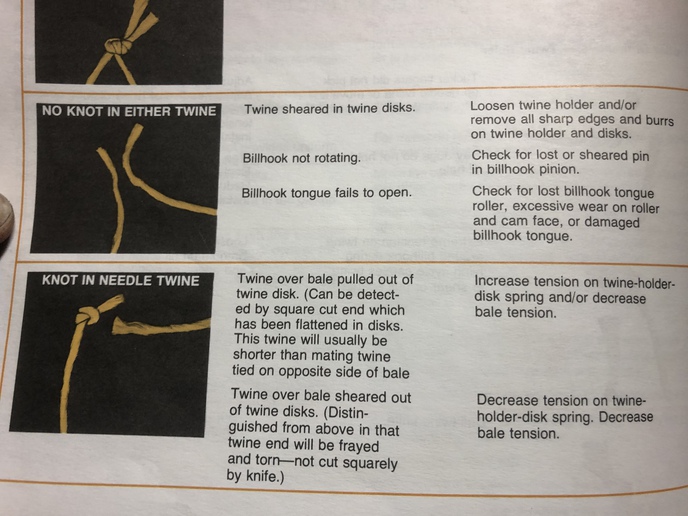

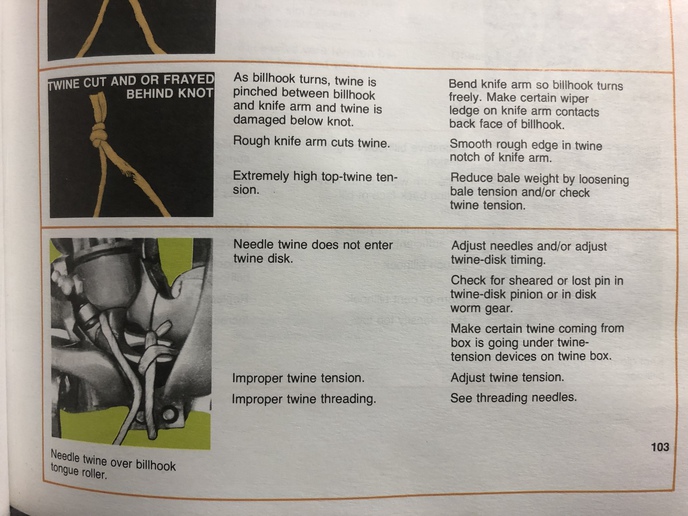

We are getting, sometimes, two pigtails with curls but no knot. This usually happens when we are baling through a patch where there is some moisture in the bottom of the windrow. It's been so rainy this summer, that we almost never have whole fields of completely, perfectly dry hay. When this happens, sometimes there is a knot in the bale, but it's loose and pulls out as the bale expands at the end of the chamber

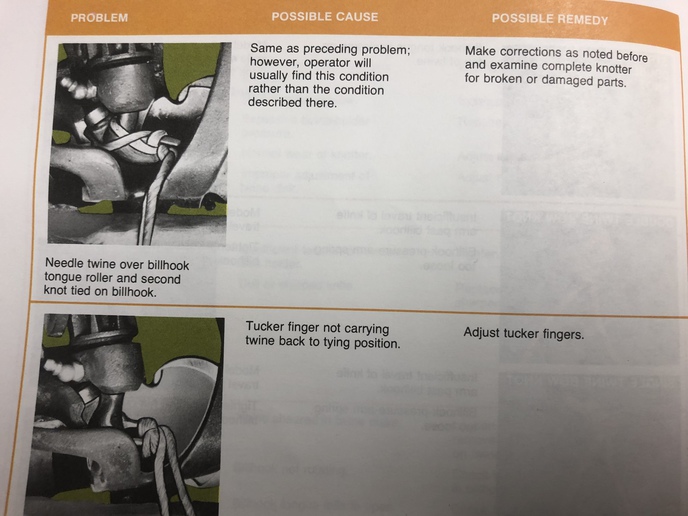

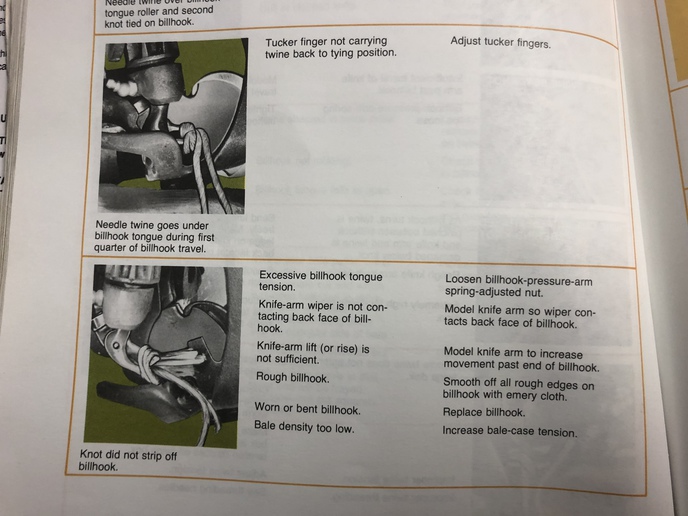

We also, once in a while, less often, will get knots caught on the billhook. This is much more rare.

Why are we thinking twine discs? What have we eliminated?

We've looked at wiper arm brass balls, both are rolling fine and appear to be not worn too small.

We have adjusted both wiper arms to wipe tightly.

We have eliminated hay dog springs... I did have one that had recently broken. We replaced it.

Tucker fingers are working properly.

We DO want to look at knotter timing, and maybe the needle carriage brake, because my brother says that he can hear the plunger sometimes clicking against the needle safety stop. I've never adjusted this.

We believe that the billhook isn't worn, since it has no trouble pulling plastic twine through to make a good, tight knot.

Now, he managed to make a couple of loads at the end of the day yesterday with no breakage, but to do that, he had to...

Shorten the bales just a touch.

Run the tractor quite a bit below the 540 PTO RPM mark (note that we always already run this baler a touch below the 540 mark)

Our working theory is this:

The sisal is thicker and should (should being the operative term) hold better in the twine discs than plastic. BUT, sisal also pulls much... much harder around the bale in the chamber. We believe that this outweighs the other effect... which means that sisal, in the end, is harder to hold.

We believe that the twine discs are just plain failing to hold the twine when we get the pigtails with no knots... or when we get a loosely formed knot that pulls through.

We also believe that the twine discs could be giving some slack to the twine as the wiper arm tries to wipe off the knot... so, instead of the twine being held taught, and the wiper arm getting a good wipe... the wiper arm is taking ups slack in the twine, instead of wiping... and then the knot hangs.

We believe that all of the solutions: shortening bales...lower RPMs...needing to bale bone dry hay... all are things that lessen the twine's tendency to pull out of the twine discs by either reducing the amount of pressure that is packed in the bale, reducing the distance of twine and tension that needs to be held, or, in the case of mostly dry hay with a little moisture... that little bit of moisture makes the hay "sticky" and sisal won't slide very well... so bone dry hay bales the best.

The twine disc timing seems to be OK. We could try tightening the springs... my brother says that some people run with double springs on these old balers...

If they aren't that expensive, I'm also considering getting new discs and putting them in.

The problem is, as far as we know, there is no field test for this... as in... I don't think the knotter manual has a spec that says... "pull on twine with force meter and twine disc should hold with X amount of force" It seems like something that needs to be diagnosed by symptoms only.

OK. Please... ask questions if I can clarify anything.

Critique away.

Thanks

Thanks.

Here are the symptoms:

Baler makes great knots with plastic twine. I just don't run it, because the plastic burns on the thrower belt. (Although, I'm making shorter bales now, I could revisit...)

We are getting, sometimes, two pigtails with curls but no knot. This usually happens when we are baling through a patch where there is some moisture in the bottom of the windrow. It's been so rainy this summer, that we almost never have whole fields of completely, perfectly dry hay. When this happens, sometimes there is a knot in the bale, but it's loose and pulls out as the bale expands at the end of the chamber

We also, once in a while, less often, will get knots caught on the billhook. This is much more rare.

Why are we thinking twine discs? What have we eliminated?

We've looked at wiper arm brass balls, both are rolling fine and appear to be not worn too small.

We have adjusted both wiper arms to wipe tightly.

We have eliminated hay dog springs... I did have one that had recently broken. We replaced it.

Tucker fingers are working properly.

We DO want to look at knotter timing, and maybe the needle carriage brake, because my brother says that he can hear the plunger sometimes clicking against the needle safety stop. I've never adjusted this.

We believe that the billhook isn't worn, since it has no trouble pulling plastic twine through to make a good, tight knot.

Now, he managed to make a couple of loads at the end of the day yesterday with no breakage, but to do that, he had to...

Shorten the bales just a touch.

Run the tractor quite a bit below the 540 PTO RPM mark (note that we always already run this baler a touch below the 540 mark)

Our working theory is this:

The sisal is thicker and should (should being the operative term) hold better in the twine discs than plastic. BUT, sisal also pulls much... much harder around the bale in the chamber. We believe that this outweighs the other effect... which means that sisal, in the end, is harder to hold.

We believe that the twine discs are just plain failing to hold the twine when we get the pigtails with no knots... or when we get a loosely formed knot that pulls through.

We also believe that the twine discs could be giving some slack to the twine as the wiper arm tries to wipe off the knot... so, instead of the twine being held taught, and the wiper arm getting a good wipe... the wiper arm is taking ups slack in the twine, instead of wiping... and then the knot hangs.

We believe that all of the solutions: shortening bales...lower RPMs...needing to bale bone dry hay... all are things that lessen the twine's tendency to pull out of the twine discs by either reducing the amount of pressure that is packed in the bale, reducing the distance of twine and tension that needs to be held, or, in the case of mostly dry hay with a little moisture... that little bit of moisture makes the hay "sticky" and sisal won't slide very well... so bone dry hay bales the best.

The twine disc timing seems to be OK. We could try tightening the springs... my brother says that some people run with double springs on these old balers...

If they aren't that expensive, I'm also considering getting new discs and putting them in.

The problem is, as far as we know, there is no field test for this... as in... I don't think the knotter manual has a spec that says... "pull on twine with force meter and twine disc should hold with X amount of force" It seems like something that needs to be diagnosed by symptoms only.

OK. Please... ask questions if I can clarify anything.

Critique away.

Thanks