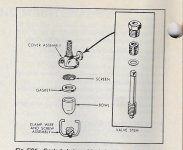

Wow, setting for 8 years? Inside or outside? Have a battery float charger on it? Ran when parked? You have a vapor lock. 1st, the Sediment Bulb Valve gets opened to the 'OPEN 2 TURNS' mark on the knurled Valve Stem Knob, The 'FULL' setting opens the reserve flow inlet - the one on the bottom of Bulb with attached screen that goes up into gas tank and you don't see. 2nd, loosen Bulb top clamp and open Valve a tad. Gas should flow. No? Your system may have one or more obstructions. 3rd step is to perform the Fuel Flow Test with a cold engine. Pass? Carb seems to be working sufficiently. Fail? Begin the step by step problem solving method to determine the true root cause. Start at fuel tank and work downstream. The tractor fuel tank has a vent on the top. It gets plugged after 75+ years of working. It is not easy to get to and can only be cleared by removing the tank itself. It takes a minute to blow out the small vent hole on the dome but it is just a time consuming project doing so as the tank is bolted to the bottom of the hood and there are several other parts that need to removed first in order to get the hood & tank assembly off. In addition, the fuel tank itself will collect dirt, debris, rust, and chaf over years of normal usage. Total removal, boiling, cleaning, and coating of inside of tank is done by some but can be expensive. There are THREE filter screens in the fuel system. First is the internal one on the bottom of the Sediment Bulb. I advise not to just remove the Bulb until a last resort. The Bulb uses a 1/8" NPT male thread and the tank has the female end. Get the tank boogered up and it may be junk. The 2nd Filter Screen is the round, flat, fine mesh brass one that seals to the glass bowl. The 3rd Filter Screen is the one most forgotten or often neglected but the most important one when doing PM. This screen is soldered to the end of the Fuel Inlet brass elbow that screws into the Carb side. The APN-9194 Valve Stem is the only working part on the Bulb. It has a rubber seal on the shaft that will wear out and leak over time. Some new ones are cheap vinyl and fail even faster. It is an $8 part and is the only one you need when doing repairs. You do not need to buy an entire new Sediment Bulb Assembly. The Valve Stem comes with the knurled knob and the 8-32 screw and lockwasher that fastens it to the stem. Many knobs get lost in the field as they can loosen and fall off. Use dab of Threadlocking goop when putting a new stem on and that will never happen. When seal wears and its time for a new stem, you'll get a new knob as well. Finally, use the OEM 1/4" SS fuel line from Stem to Carb inlet. Fuel and brake lines use an industry standard special thread size. It is 7/16-24 UNS - Unified National Special. Never use anything else. Also never user rubber, copper, plastic, nylon, aluminum, or other material for the fuel line.

Tim Daley (MI)