Tim PloughNman Daley RIP

Well-known Member

OK, a 6V battery does not mean the entire wiring is correct for the 6V/POS GRN system. Is it a front mount or a side mount distributor? Do plugs get fouled? Why did you replace all those parts? Did coil prove defective? Tune-Up is done when all else is right. If a front mount, were points gapped at .015" and timing set right? Unit can only be mounted one correct way otherwise it will be destroyed. Cleaning tank and fresh gas are fine, but the Fuel Flow Test should be done first. Pass? Move on to electrical. Fail? Get into possible causes working downstream and DO NOT just start pulling parts off like Sediment Bulb. Did you take the fuel inlet brass elbow off the line and remove it to clean the internal screen? Remove gas cap. The gas tank has a dome and vent hole on top. It’s only about a 1/16” diameter hole but 75+ years of use and neglect can cause it to plug up with dirt and debris. The entire hood and other parts must be removed to get to it as the tank is bolted to the hood. So many were never done. It takes a minute to blow out the vent hole but takes hours to pull hood off. Plugged vent sometimes can cause a vapor lock that restricts fuel flow. On to electrical: If a front mount system, do you have all the correct parts in the system? Is the OEM 9N-12250 BALLAST RESISTOR in the circuit? Is the Generator a 6V 3-Wire/3-Brush 11.5A unit or a 3-Wire/2-Brush 20A unit? Is the belt tensioning device attached to the GEN? Is the Voltage Regulator on GEN? Is Starter Motor 3-Wire with RELAY (SOLENOID) attached? Is carb the OEM Marvel-Schebler TSX-241 model or a new Cheena import? Did you remove carb to "clean" it? What did you do to it? At reinstall did you put all the settings at the initial spec settings as per manuals? Did you mess with any settings after the tractor was running? Get your manuals and related documents to do more homework. See if this info helps you some then report back with a follow up and findings.I have replaced coil, condenser, drained tank, cleaned sediment bowl and screen, refilled with rec gas, cleaned carb, cleaned plugs, cleaned points and regapped. It is still a 6V system.

Im at a loss?

Tim Daley (MI)

Attachments

-

FUEL TANK & CARB PG 1.jpg770.3 KB · Views: 7

FUEL TANK & CARB PG 1.jpg770.3 KB · Views: 7 -

FUEL TANK & CARB PG 2.jpg857.1 KB · Views: 8

FUEL TANK & CARB PG 2.jpg857.1 KB · Views: 8 -

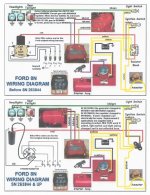

FUEL TANK & CARB PG 3.jpg682.9 KB · Views: 9

FUEL TANK & CARB PG 3.jpg682.9 KB · Views: 9 -

FRONT MOUNT COIL STATIC TEST.png704.5 KB · Views: 9

FRONT MOUNT COIL STATIC TEST.png704.5 KB · Views: 9 -

FORD OEM 9N-12250 BALLAST RESISTOR.jpg57.8 KB · Views: 9

FORD OEM 9N-12250 BALLAST RESISTOR.jpg57.8 KB · Views: 9 -

8N WIRING DIAGRAMS.jpg182.8 KB · Views: 11

8N WIRING DIAGRAMS.jpg182.8 KB · Views: 11 -

FORD N-SERIES TRACTOR FUEL FILTER SYSTEM.jpg46 KB · Views: 7

FORD N-SERIES TRACTOR FUEL FILTER SYSTEM.jpg46 KB · Views: 7