Tomorrow i will receive back the Simms injection Pump i sent off to Dieseltech for a rebuild. I'm kind of excited to get this Ford 5000 running. I hope everything works as it should. New oil in the engine, SOS tranny and Rear end. If you remember the tranny and the rear end had no oil in them. I did find the park switch wires were bypassed bypassed cuz the switch in the tranny wasn't working. It's all fixed now. This tractor speedo does have 5000 hrs on it so hopefuly the engine isn't worn out. Stay tuned for a video of it starting and running

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter nashranch

- Start date

Bern

Well-known Member

- Location

- Mount Vernon, WA

Engine starts and sounds really good - looks like Dieseltech served you well on that pump. As for the SOS, isn't Tim (Dopp Creek) pretty much your neighbor? He knows those transmissions pretty well by now, I'll volunteer him to go over and look at it for you!It does start and run real well..had it out of the shop for test drive. SOS tranny is slipping in the higher gears... I'm afraid i need a band adjustment...i need a manual for this to do some pressure testing. Any help would be appreciated Bern

Otherwise yes, I would suggest getting a manual because I'm not typing out the procedure for either the band adjustment or pressure testing. Also, don't rule out the possibility of a slipping torque limiting clutch in the flywheel. I'd suspect this if the slippage feels like it's directly related to engine load rather than specific gears.

FYI, I rebuilt Tim's 5000 SOS 6 years ago. As part of a class project, I recorded some pressure testing for the benefit of my students. Two videos are linked below the picture, one before and one after the repair. In both videos, two separate tests were performed. The first half of the test measured the 3 different band pressures at the same time, while the second half of the test showed the pressure at band #1, pump pressure, and lube pressure.

As it turned out, there was major internal leakage in the direct drive clutch circuit, which shares fluid with band #1 servo. You can see in the "before repair" video that the band #1 pressure was noticeably lower than the other two bands whenever it was applied. In addition, you can see lube pressure dropping pretty much to zero while #1 band was applied.

Picture shows the hookup for the first part of the test, checking the 3 band pressures. #1 band test port is on the RH side of the tractor.

Here are the videos:

Before repair: https://skagit.hosted.panopto.com/Panopto/Pages/Viewer.aspx?id=e14c2ddd-46c9-42ce-8290-a8740016110c

After repair: https://skagit.hosted.panopto.com/Panopto/Pages/Viewer.aspx?id=623b03e4-4cd8-4ec9-8e12-a8b300092972

Thanks Bern..i think dopp creek Tim is about 2 hours North of me so not a neighbor. When i first started the tractor and backed out of of shop just fine. Then hit 1 st, then 2nd, then 3rd, 4th was sluggish, 5 6. And 7 were non existent. Then 9 and 10 didn't want to but they did sort of. The more i ran the worse it got.. ity close to the shop door and had to get off and remove the muffler to get it in the shop door.. it didn't want to move but then it did in 1st...Still sound like a torque limit clutch to you???

Bern

Well-known Member

- Location

- Mount Vernon, WA

Tim visits me on occasion and I'm 4 hours north of him, so it should be no big deal for him to run down and see you!Thanks Bern..i think dopp creek Tim is about 2 hours North of me so not a neighbor. When i first started the tractor and backed out of of shop just fine. Then hit 1 st, then 2nd, then 3rd, 4th was sluggish, 5 6. And 7 were non existent. Then 9 and 10 didn't want to but they did sort of. The more i ran the worse it got.. ity close to the shop door and had to get off and remove the muffler to get it in the shop door.. it didn't want to move but then it did in 1st...Still sound like a torque limit clutch to you???

Based on your description, it sounds like the longer you run it the worse it gets. If this is true, then no, I'm not suspecting a torque limiting clutch, but rather a pressure problem. Cold oil masks an internal leak, as the oil warms up the internal leakage gets worse. Sounds like whoever had it before you was getting ready to work on it, which would explain why there was no oil in it.

Try it again with cold oil and report back exactly which gears drive and which don't, make a list from R2 all the way to 10. Or, get a manual for it and study the pressure testing part of it, then watch the videos and it will make more sense.

Yep will do that tomorrow. The switch wires to the switch in the tranny were bypassed. i did not see any sign of the oil pan on the bottom that it had been opened up. I did check continuity on those before i dropped the pan and found the switch. I was able to adjust the switch and make it start working as it should. Of course i had no idea there were other tranny problems.

Dopp Creek

Member

Here's a copy of my spreadsheet from my testing. It was invaluable in diagnosing the problems.

| GEAR | BAND 1 (C/H) | BAND 2 | BAND 3 | |

| P | 0 | 0 | 0 | |

| R2 | 0 | 180 | 0 | |

| R1 | 110 | 160 | 0 | |

| N | 110 | 160 | 160 | |

1 | 110 | 160 | 0 | |

2 | 110 | 160 | 0 | |

3 | 0 | 190 | 0 | |

4 | 0 | 190 | 0 | |

5 | 110 | 0 | 140 | |

6 | 110 | 0 | 140 | |

7 | 0 | 0 | 160 | |

8 | 0 | 0 | 160 | |

9 | 110 | 105 | 95 | |

10 | 0 | 180 | 160 | |

| All values at 800 rpm; fluid temp 85F | ||||

showcrop

Well-known Member

I think that if you think about the over-all situation with your SOS it makes two hours a VERY, VERY, nearby neighbor.Thanks Bern..i think dopp creek Tim is about 2 hours North of me so not a neighbor. When i first started the tractor and backed out of of shop just fine. Then hit 1 st, then 2nd, then 3rd, 4th was sluggish, 5 6. And 7 were non existent. Then 9 and 10 didn't want to but they did sort of. The more i ran the worse it got.. ity close to the shop door and had to get off and remove the muffler to get it in the shop door.. it didn't want to move but then it did in 1st...Still sound like a torque limit clutch to you???

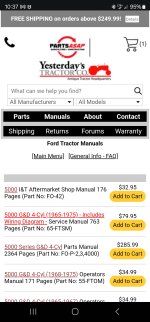

https://www.yesterdaystractors.com/FO42_5984.htm

Getting ready to order this shop manual from YT. Hopefully this will give the right info my SOS pressure testing and Band adjustments

Getting ready to order this shop manual from YT. Hopefully this will give the right info my SOS pressure testing and Band adjustments

Here's my cold oil test this morning Bern.

Park... Doesn't lock up. Wants to roll forward.

R2... Seemed to back up ok out of the shop

R1.. Same as R2

N

1.. Moves forward but not fast.. Got jerky

2 same as 1

3 same as 1

4 same as 1

5 barely creeps but does move forward

6 same as 5

7 no movement

8 barely moves

9 seems to go ok

10 send to go ok.... Held it back though cuz i ran outta room.

Now after running it for while R1 and R2 still working ok. Oil must be hotter now cuz 1st barely got me back into shop. I definitely got problems

Park... Doesn't lock up. Wants to roll forward.

R2... Seemed to back up ok out of the shop

R1.. Same as R2

N

1.. Moves forward but not fast.. Got jerky

2 same as 1

3 same as 1

4 same as 1

5 barely creeps but does move forward

6 same as 5

7 no movement

8 barely moves

9 seems to go ok

10 send to go ok.... Held it back though cuz i ran outta room.

Now after running it for while R1 and R2 still working ok. Oil must be hotter now cuz 1st barely got me back into shop. I definitely got problems

Destroked 450

Well-known Member

- Location

- Harned, Ky

You definitely have a band issue on number 2 or 3 band

Park is controlled by number 2 and 3 bands being applied by spring pressure, hydraulic pressure releases the bands

In the park position or anytime the engine is not running spring pressure automatically applies those two bands to lock the drums thus creating park

There is no mechanical park like in automotive transmissions

Park is controlled by number 2 and 3 bands being applied by spring pressure, hydraulic pressure releases the bands

In the park position or anytime the engine is not running spring pressure automatically applies those two bands to lock the drums thus creating park

There is no mechanical park like in automotive transmissions

Bern

Well-known Member

- Location

- Mount Vernon, WA

I agree with Destroked. Get those bands adjusted and then see what changes before we jump to conclusions.Here's my cold oil test this morning Bern.

Park... Doesn't lock up. Wants to roll forward.

R2... Seemed to back up ok out of the shop

R1.. Same as R2

N

1.. Moves forward but not fast.. Got jerky

2 same as 1

3 same as 1

4 same as 1

5 barely creeps but does move forward

6 same as 5

7 no movement

8 barely moves

9 seems to go ok

10 send to go ok.... Held it back though cuz i ran outta room.

Now after running it for while R1 and R2 still working ok. Oil must be hotter now cuz 1st barely got me back into shop. I definitely got problems

Yep i will do that as soon as i get a manual that tells me how to do it. I need three 1/8" pipe gages right? Say 200lbs gagesI agree with Destroked. Get those bands adjusted and then see what changes before we jump to conclusions.

Dopp Creek

Member

I just did them one location at a time. Seems like I used a 12” grease gun hose and a bell reducer that was 1/8” pipe on one end and 1/4” pipe on the other since my gauge had 1/4” threads.Yep i will do that as soon as i get a manual that tells me how to do it. I need three 1/8" pipe gages right? Say 200lbs gages

Traction disconnect out, gauge hooked up to band #1 port and cycle through each gear and record your pressures. Move to port 2 and repeat the sequence, then port 3. This would be your oil cold test. Take it out and drive around in your most stable gears for 20 minutes to warm up the oil and then repeat. A temp gun on the trans housing to record temps is a valuable data point for analysis when comparing hot to cold.

I have a spreadsheet with all the part numbers I used in rebuilding mine when you get to that point.

Sean in PA

Well-known Member

Slight drifting forward when in Park is fairly normal, even when everything else is adjusted and working properly.

Similar threads

- Replies

- 7

- Views

- 990

- Replies

- 8

- Views

- 1K

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy