lastcowboy32

Well-known Member

So,

It's funny, because a bunch of us were just spun around trying to help someone with an old N tractor that wouldn't start... even though the starter was turning some, but the battery cables were getting hot.

I couldn't find the end game of that diagnosis, but the last notion was that the starter had a partial short.

Well... we recently finished baling hay with our Mahindra 6075. (a 76hp diesel tractor... not an N)... I parked it and shut it off next to an overloaded haywagon to skim some bales off the top into the loader, so I could pull the rest of the load into the barn.

Got back on to start it? The starter gave a couple of grunts and puked.

It was getting dark, so I just pulled the wagon away with the other tractor and got it under cover.

Next morning, I went out there with a Insta-Power and our car with jumper cables.

With any jumper combination, best I could get was a couple grunts out of the starter, but not enough to start the tractor.

I pulled the battery and checked the tractor battery on my charger... says it's good. But, the positive terminal on the cable assembly is woefully corroded... so with any jump-start configuration, I'm probably not getting much help from the tractor battery itself. The car battery/alternator was getting loaded just from turning the tractor's keyswitch on (which engages an intake heater/glow plug)

So, I took the insta power right over to the starter posts and bypassed everything. That would get me about a half second of starter action with every switch on of the insta-power... but no more.

The cable to the insta-power got HOT...after a few cycles.

So... I'm figuring, starter must have a partial short.

Take the starter off, test it, unloaded, off of the tractor with the insta-power... the starter turns, and keeps turning, but the insta-power drops to about 10V.

At this point, I need to say... I KNOW the positive terminal on the battery wiring harness was hanging by a thread... I knew that I was going to need to do something about that... BUT... I figured that I could at least get the tractor started, so I could bring it over by the barn.

The fact that no jumper method possible could start the tractor and the unloaded test with the insta-power told me... that I had a partial short in the starter.

So... took the starter to a reputable shop.

Good news/bad news... Good news: He says it's a Lucas starter. Good reputation. Heavy Duty. He works on them and deals in them. Has one right on the shelf.

Bad news: according to his bench test, the starter is fine. Says that all batteries drop a volt or two during cranking... to which I say... "Unloaded???"... he shrugs. Says that insta-powers are crap, jumper cables are crap. To get a diesel started, you need a good, full size battery and excellent connection...better than 20 dollar jumper cables or an insta-power.

So... he says... Go over to the local battery shop and have them re-do the battery cable.

I pull the positive and negative cables, take them over there. the tech says..."it's 4AWG, that should be OK.. but you definitely need a new end..." We talk a little more, and he says, it's just a little 25 horse diesel, right? I'm like...no... full size utility farm tractor... he changes his tune a little... says maybe 4 AWG is a little light.

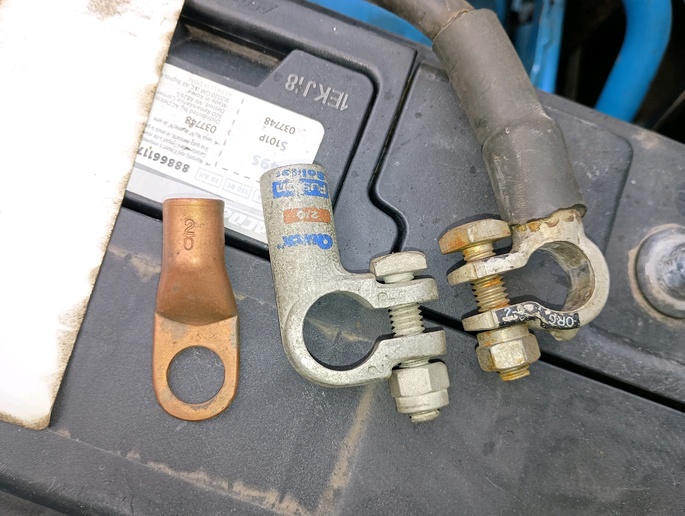

I don't want to have this as a variable anymore... so... it cost me 57 bucks, but I now have a 1/0 stranded welder cable with new clamps and lugs for both the battery to starter and battery to chassis ground connections...

Installing tonight. If that does the trick? It'll be money well spent.

It's funny, because a bunch of us were just spun around trying to help someone with an old N tractor that wouldn't start... even though the starter was turning some, but the battery cables were getting hot.

I couldn't find the end game of that diagnosis, but the last notion was that the starter had a partial short.

Well... we recently finished baling hay with our Mahindra 6075. (a 76hp diesel tractor... not an N)... I parked it and shut it off next to an overloaded haywagon to skim some bales off the top into the loader, so I could pull the rest of the load into the barn.

Got back on to start it? The starter gave a couple of grunts and puked.

It was getting dark, so I just pulled the wagon away with the other tractor and got it under cover.

Next morning, I went out there with a Insta-Power and our car with jumper cables.

With any jumper combination, best I could get was a couple grunts out of the starter, but not enough to start the tractor.

I pulled the battery and checked the tractor battery on my charger... says it's good. But, the positive terminal on the cable assembly is woefully corroded... so with any jump-start configuration, I'm probably not getting much help from the tractor battery itself. The car battery/alternator was getting loaded just from turning the tractor's keyswitch on (which engages an intake heater/glow plug)

So, I took the insta power right over to the starter posts and bypassed everything. That would get me about a half second of starter action with every switch on of the insta-power... but no more.

The cable to the insta-power got HOT...after a few cycles.

So... I'm figuring, starter must have a partial short.

Take the starter off, test it, unloaded, off of the tractor with the insta-power... the starter turns, and keeps turning, but the insta-power drops to about 10V.

At this point, I need to say... I KNOW the positive terminal on the battery wiring harness was hanging by a thread... I knew that I was going to need to do something about that... BUT... I figured that I could at least get the tractor started, so I could bring it over by the barn.

The fact that no jumper method possible could start the tractor and the unloaded test with the insta-power told me... that I had a partial short in the starter.

So... took the starter to a reputable shop.

Good news/bad news... Good news: He says it's a Lucas starter. Good reputation. Heavy Duty. He works on them and deals in them. Has one right on the shelf.

Bad news: according to his bench test, the starter is fine. Says that all batteries drop a volt or two during cranking... to which I say... "Unloaded???"... he shrugs. Says that insta-powers are crap, jumper cables are crap. To get a diesel started, you need a good, full size battery and excellent connection...better than 20 dollar jumper cables or an insta-power.

So... he says... Go over to the local battery shop and have them re-do the battery cable.

I pull the positive and negative cables, take them over there. the tech says..."it's 4AWG, that should be OK.. but you definitely need a new end..." We talk a little more, and he says, it's just a little 25 horse diesel, right? I'm like...no... full size utility farm tractor... he changes his tune a little... says maybe 4 AWG is a little light.

I don't want to have this as a variable anymore... so... it cost me 57 bucks, but I now have a 1/0 stranded welder cable with new clamps and lugs for both the battery to starter and battery to chassis ground connections...

Installing tonight. If that does the trick? It'll be money well spent.