john in la

Well-known Member

I need to cut a bunch of 29 and 24 gauge metal panels like you use for roofing or to build a pole barn.

Not looking for a make shift way to cut them such as using a wood circular saw blade turned backwards.

I have some good aviation snips but that seems like a lot of work to cut about 200 feet of cuts.

Most of the cuts will be across the panels 3 foot width but I do have to trim some down the panel to width.

From what I read a nibbler is what I need to cut across the humps of the panels as a shear is more for cutting flat like down the panel. On top of that a nibbler is kind of a high priced tool to buy for a one time use.

With all this I am kind of in a compromize mode.

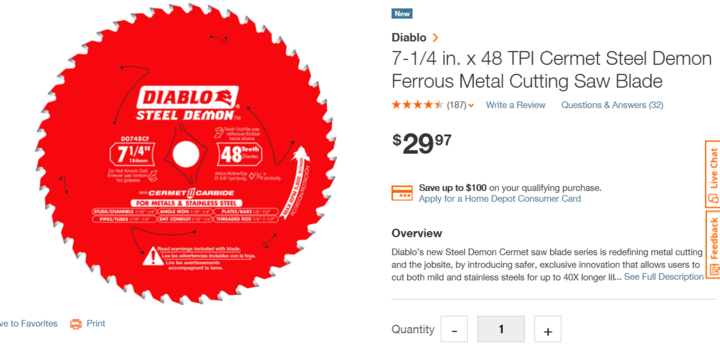

Trying to decide if I should get metal cutting blade like Diablo or Irwin makes or try the nibbler attachment they make for a drill because I do not know what would be best to try.

So if we consider this is a one time use tool what is the best tool I can get and keep the price within reason.

Thanks in advance for your advise.

Not looking for a make shift way to cut them such as using a wood circular saw blade turned backwards.

I have some good aviation snips but that seems like a lot of work to cut about 200 feet of cuts.

Most of the cuts will be across the panels 3 foot width but I do have to trim some down the panel to width.

From what I read a nibbler is what I need to cut across the humps of the panels as a shear is more for cutting flat like down the panel. On top of that a nibbler is kind of a high priced tool to buy for a one time use.

With all this I am kind of in a compromize mode.

Trying to decide if I should get metal cutting blade like Diablo or Irwin makes or try the nibbler attachment they make for a drill because I do not know what would be best to try.

So if we consider this is a one time use tool what is the best tool I can get and keep the price within reason.

Thanks in advance for your advise.