Bob Bancroft

Well-known Member

- Location

- Aurora NY

I should be in the field. But since we're getting the water we didn't get in the first half of the year, I'm fiddling around the shop.

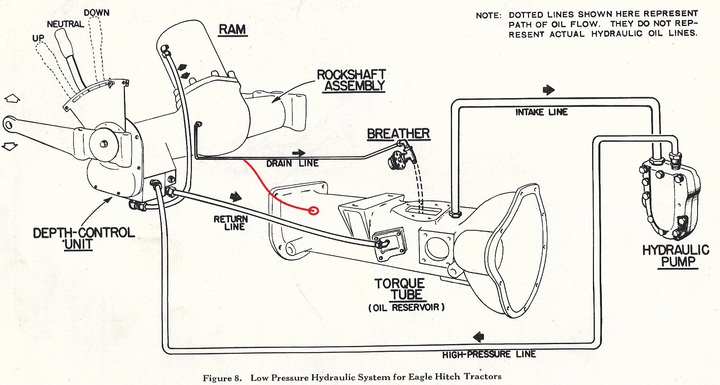

My newly acquired VAC has a 3/8" copper line running from the base of the Eagle hitch to a tee on the steering gear. Operators manual shows it. This apparently acts as a breather, as well as a drain for any seepage from the lift cylinder. The steering gear is open to the torque housing. Someone has installed a little brass valve on the top of the tee. I think I finally understand that this should be a breather for the system. So I removed the shut off, and fastened about an 18" piece of clear plastic tube to the top of the tee. When I lower the lift, a little oil pushes right up out of the tube. I'm assuming several possibilities. Maybe the lift cyl. leaks by more than it should. Maybe the cavity under the lift cyl. has filled with more oil than should be there because the system hasn't been properly vented. It also looks like I should remove the left platform and clean the rear end breather.

Am I correct about a breather on the tee? I'm thinking of running the tube up to some kind of container which would act as an air/oil separator.

Before I do any rebuilding[which would be this coming winter anyhow] I will make sure everything can breath like it should, and see if things straighten out.

My newly acquired VAC has a 3/8" copper line running from the base of the Eagle hitch to a tee on the steering gear. Operators manual shows it. This apparently acts as a breather, as well as a drain for any seepage from the lift cylinder. The steering gear is open to the torque housing. Someone has installed a little brass valve on the top of the tee. I think I finally understand that this should be a breather for the system. So I removed the shut off, and fastened about an 18" piece of clear plastic tube to the top of the tee. When I lower the lift, a little oil pushes right up out of the tube. I'm assuming several possibilities. Maybe the lift cyl. leaks by more than it should. Maybe the cavity under the lift cyl. has filled with more oil than should be there because the system hasn't been properly vented. It also looks like I should remove the left platform and clean the rear end breather.

Am I correct about a breather on the tee? I'm thinking of running the tube up to some kind of container which would act as an air/oil separator.

Before I do any rebuilding[which would be this coming winter anyhow] I will make sure everything can breath like it should, and see if things straighten out.