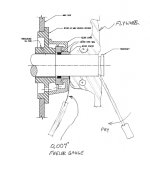

Replacing the flywheel on a 1948 A, part no. A3264R. My shop manual shows end play of .005-.010 moving flywheel in and out on the shaft. I assume that

the play is controlled by the lock nut on the shaft. I am not sure what the torque is for the flywheel bolts. Pulling down tight with a 1/2 pull handle

and socket leaves a slight amount of movement in the flywheel to shaft joint. Is this joint supposed to be tight, and what is the torque for the bolts?

Splines on flywheel and shaft look good. Thanks for any help/advice in this matter.

Thanks,

WL McCabe

the play is controlled by the lock nut on the shaft. I am not sure what the torque is for the flywheel bolts. Pulling down tight with a 1/2 pull handle

and socket leaves a slight amount of movement in the flywheel to shaft joint. Is this joint supposed to be tight, and what is the torque for the bolts?

Splines on flywheel and shaft look good. Thanks for any help/advice in this matter.

Thanks,

WL McCabe