Hello all,

My wife and I recently bought a house with 5 acres of fairly flat ground which we are hoping to get some grass started in and also cut an arena. Of course to maintain this size place, I decided I needed a small tractor and some implements. So I can down the road and found an International 300 Utility for $800.00 that runs like a champ but I can tell has been a bit neglected when it comes maintenance. However, upon starting to look at everything that needs done, I have come to realize I have VERY limited knowledge of tractors.

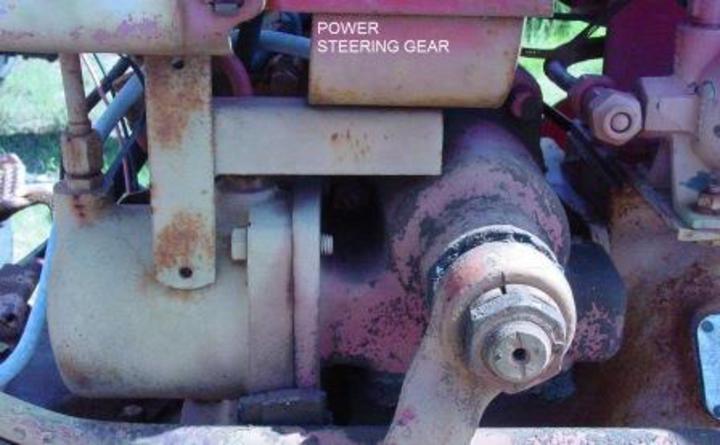

I have greased every cert I can find and replaced those which wouldn't take grease but now I'm on to fluids. Unfortunately, I don't know which pan or filler goes to which fluid. I also don't know what systems run off the same reservoir. I was hoping someone might be able to get me pointed in the right direction.

I have shop manual for it but it is for several models and a most of the pictures don't reference the 300 so I'm kind of lost trying to follow it. I'm sure it will make more sense as I become more familiar with the tractor.

Any help related to the topic of fluids or any other topics is greatly appreciated.

Thanks!

My wife and I recently bought a house with 5 acres of fairly flat ground which we are hoping to get some grass started in and also cut an arena. Of course to maintain this size place, I decided I needed a small tractor and some implements. So I can down the road and found an International 300 Utility for $800.00 that runs like a champ but I can tell has been a bit neglected when it comes maintenance. However, upon starting to look at everything that needs done, I have come to realize I have VERY limited knowledge of tractors.

I have greased every cert I can find and replaced those which wouldn't take grease but now I'm on to fluids. Unfortunately, I don't know which pan or filler goes to which fluid. I also don't know what systems run off the same reservoir. I was hoping someone might be able to get me pointed in the right direction.

I have shop manual for it but it is for several models and a most of the pictures don't reference the 300 so I'm kind of lost trying to follow it. I'm sure it will make more sense as I become more familiar with the tractor.

Any help related to the topic of fluids or any other topics is greatly appreciated.

Thanks!