Dave H (MI)

Well-known Member

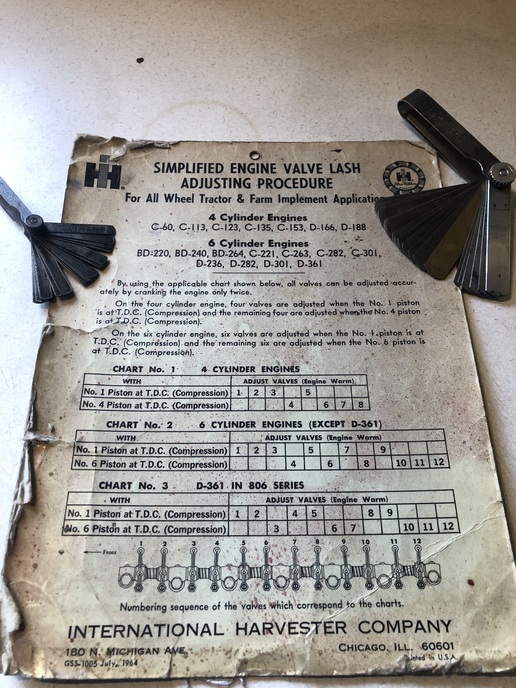

Can y'all walk me thru the process? I will be setting them cold as this tractor is in reassembly from having some work done. When I put the head on I know I put 1 and 4 were at TDC. I have been reading a lot of old posts but it seems there are a lot of opinions on just how to do this. I think I have done it once before but we are talking a very long time ago. The oil pan is still off the tractor. I'm a little confused on some of these old posts I read about setting the intake at one point and the exhaust at another point...but I cannot see the valves so not sure how I would know when one is starting to open or close. Hope this makes sense. Been a long road with some health issues in the middle of it. Going to be a big deal for me when this tractor is all back together. More so if it runs. Thanks in advance for any help you can be.