Ok, my '66 - 4020 does not have a "BR" port on the PTO valve to test the PTO brake pressure? Yes I'm sure. It only has a "Clutch" and a "PTO" port. I physically removed the inching pedal and there is not a "BR" port.

To resolve the problem of the PTO not shutting off at 1900 RPM, I shimmed the oil pressure to 185 PSI. PTO worked great however, the book says it needs to be 150psi. Worried about the pump longevity, additional oil seals and why do I need 35 psi extra?

Called a JD dealer and spoke to them. We checked the pto with tractor off, and the PTO will turn by hand. Said that's good, PTO clutches should not be warped.

He looked in his service manual and asked about the shifting, 3-point operation, rear remotes, PTO and "CL" ports on the side of the PTO valve and all that checked out ok.

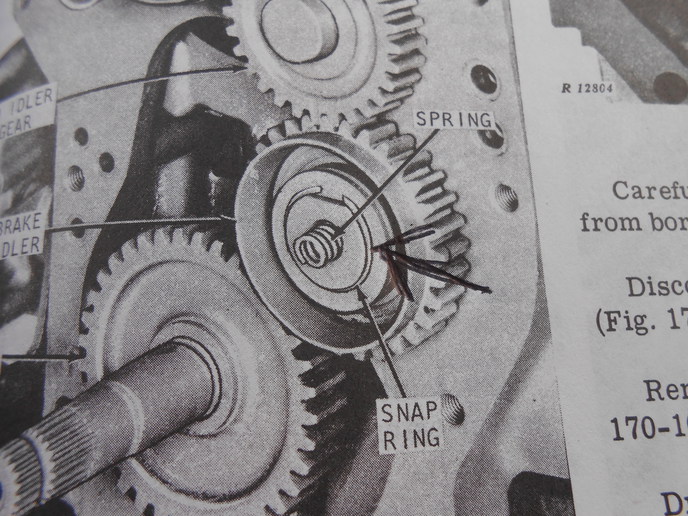

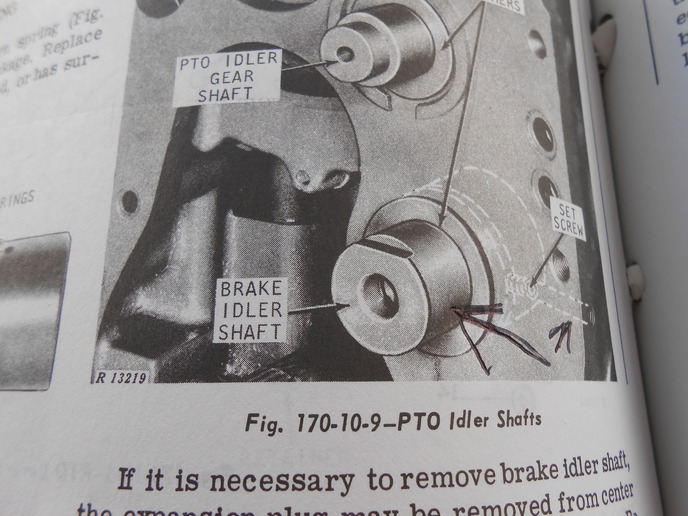

Basically sounds like the PTO brake lining is toast. Sounds like the increased pressure on the oil regulator was enough to overcome the lining failure and possibly metal to metal on the PTO brake in the transmission.

Sounds like the thing requires 2 splits to get the PTO brake out for inspection.

I did ask him about the PTO free wheeling when it's shut off with an implement on the PTO. He said it's suppose to freewheel to a stop. My question is how much freewheeling does the PTO shaft do normally when NOTHING is attached to it? I would assume it SHOULD stop pretty quickly?

If the PTO shaft is stopped and the tractor is running, I cannot turn the PTO shaft by hand.

Does the PTO brake only have sufficient braking ability to stop the shaft quickly when no attachments are on the PTO? Is this a balancing act between hydraulic pressures, brake lining, etc so the implement stops, but does not grind up the PTO brake lining?

My final question is why if the brake lining is bad, do I still have pressure on the PTO that will grind up a 2x4 pushed up against it when the PTO lever is turned off at 1900 RPM? Sounds like to me I have pressure leaking past a seal and placing pressure on the clutch pack. This sounds like a faulty valve/o-ring, seal etc. Are there any check valves to the PTO clutches that could stick? Just talking out loud.

Any ideas or observations would be of great help.

Thanks.

To resolve the problem of the PTO not shutting off at 1900 RPM, I shimmed the oil pressure to 185 PSI. PTO worked great however, the book says it needs to be 150psi. Worried about the pump longevity, additional oil seals and why do I need 35 psi extra?

Called a JD dealer and spoke to them. We checked the pto with tractor off, and the PTO will turn by hand. Said that's good, PTO clutches should not be warped.

He looked in his service manual and asked about the shifting, 3-point operation, rear remotes, PTO and "CL" ports on the side of the PTO valve and all that checked out ok.

Basically sounds like the PTO brake lining is toast. Sounds like the increased pressure on the oil regulator was enough to overcome the lining failure and possibly metal to metal on the PTO brake in the transmission.

Sounds like the thing requires 2 splits to get the PTO brake out for inspection.

I did ask him about the PTO free wheeling when it's shut off with an implement on the PTO. He said it's suppose to freewheel to a stop. My question is how much freewheeling does the PTO shaft do normally when NOTHING is attached to it? I would assume it SHOULD stop pretty quickly?

If the PTO shaft is stopped and the tractor is running, I cannot turn the PTO shaft by hand.

Does the PTO brake only have sufficient braking ability to stop the shaft quickly when no attachments are on the PTO? Is this a balancing act between hydraulic pressures, brake lining, etc so the implement stops, but does not grind up the PTO brake lining?

My final question is why if the brake lining is bad, do I still have pressure on the PTO that will grind up a 2x4 pushed up against it when the PTO lever is turned off at 1900 RPM? Sounds like to me I have pressure leaking past a seal and placing pressure on the clutch pack. This sounds like a faulty valve/o-ring, seal etc. Are there any check valves to the PTO clutches that could stick? Just talking out loud.

Any ideas or observations would be of great help.

Thanks.