Hay maker2

Member

Ok, my 1965 John Deere 4020 powershift started to slip last summer, most noticeable while in 7th & 8th gear going up hill with a load. I am for sure all the gears slipped a bit, but was not noticeable.

Now we have owned this tractor since 1970 and the power shift has never been worked on so I was and I am not afraid to go the extra mile and replace something extra (O-rings / seals) since it is 50 years old and been a reliable work horse.

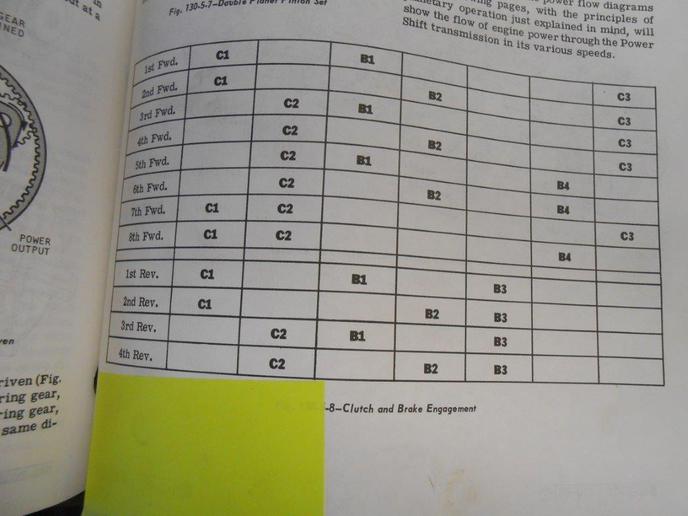

I borrowed the test gauges (the unit with all 7 gauges on it) and checked the clutch and brake packs. C1 & C2 had 50 psi on them and the C3 and the brake unit all had 160 psi. The PTO also had 160psi.

I resealed the planetary pack even though the pressures were good and replaced a few O-rings and seals here and there because there was a drip and there was no better time to replace them then now.

I disassembled the C1 & C2 clutch pack and all of the separator plates and friction plates looked great and I took them to my local dealer and they agreed that there are nothing wrong with them. This was a well seasoned mechanic that has been at the dealer for almost 40 years. He has worked on and rebuilt everything under the sun and he is always spot on, he knows his stuff. I replaced all the seals in the C1/C2 clutch pack and replaced the seals in the supply pump. This includes the 4 sealing rings that transfers the input shaft to the C1 drum. I also replaced the "plug" and sealing ring on the output shaft that transfers power to the planetary pack.

For good measures I also opened and replaced the O-Rings, Seals, and springs in the shift valve (aluminum housing) and speed select housing. Like I said, its 50 years old and I have no problem going the extra step.

Since the tractor was split, I installed a new pressure plate, springs, and a rear engine oil seal (seal was not leaking) and new gaskets and O-rings between the rear end and clutch housing.

Now, I started the tractor up and I still have the same 50 PSI on C1/C2 and everything else still has the 160 PSI. Before everyone asks, yes I did swap the gauges around to confirm that there was 50 PSI on C1/C2 and that there was not two bad gauges.

At this point I studied my service manual and decided to replace the speed control spools and the shift valve (aluminum housing and valves) because I felt that there may of been blow by at this point.

To my surprise when I started it up to night, I still have 50 PSI on C1/C2 and everything else remains 160 PSI. I am at a loss and looking for any suggestions.

The only thing that I can think of at this time is that the C1 clutch drum may have some grooves worn into it from the sealing rings, but I inspected that when I took it apart and it appeared to be fine. It was shinny where the rings ride, but I could not feel any grooves in it. I also made sure that I used the correct sealing rings since there are three different ones based upon serial numbers. Other than the clutch drum, what's the chance that there is a crack in the clutch housing allowing oil pressure to blow by????

Thanks for any and all help!!!!

Now we have owned this tractor since 1970 and the power shift has never been worked on so I was and I am not afraid to go the extra mile and replace something extra (O-rings / seals) since it is 50 years old and been a reliable work horse.

I borrowed the test gauges (the unit with all 7 gauges on it) and checked the clutch and brake packs. C1 & C2 had 50 psi on them and the C3 and the brake unit all had 160 psi. The PTO also had 160psi.

I resealed the planetary pack even though the pressures were good and replaced a few O-rings and seals here and there because there was a drip and there was no better time to replace them then now.

I disassembled the C1 & C2 clutch pack and all of the separator plates and friction plates looked great and I took them to my local dealer and they agreed that there are nothing wrong with them. This was a well seasoned mechanic that has been at the dealer for almost 40 years. He has worked on and rebuilt everything under the sun and he is always spot on, he knows his stuff. I replaced all the seals in the C1/C2 clutch pack and replaced the seals in the supply pump. This includes the 4 sealing rings that transfers the input shaft to the C1 drum. I also replaced the "plug" and sealing ring on the output shaft that transfers power to the planetary pack.

For good measures I also opened and replaced the O-Rings, Seals, and springs in the shift valve (aluminum housing) and speed select housing. Like I said, its 50 years old and I have no problem going the extra step.

Since the tractor was split, I installed a new pressure plate, springs, and a rear engine oil seal (seal was not leaking) and new gaskets and O-rings between the rear end and clutch housing.

Now, I started the tractor up and I still have the same 50 PSI on C1/C2 and everything else still has the 160 PSI. Before everyone asks, yes I did swap the gauges around to confirm that there was 50 PSI on C1/C2 and that there was not two bad gauges.

At this point I studied my service manual and decided to replace the speed control spools and the shift valve (aluminum housing and valves) because I felt that there may of been blow by at this point.

To my surprise when I started it up to night, I still have 50 PSI on C1/C2 and everything else remains 160 PSI. I am at a loss and looking for any suggestions.

The only thing that I can think of at this time is that the C1 clutch drum may have some grooves worn into it from the sealing rings, but I inspected that when I took it apart and it appeared to be fine. It was shinny where the rings ride, but I could not feel any grooves in it. I also made sure that I used the correct sealing rings since there are three different ones based upon serial numbers. Other than the clutch drum, what's the chance that there is a crack in the clutch housing allowing oil pressure to blow by????

Thanks for any and all help!!!!