Hi all and David P

Given your location David I thought you may have had something to do with Nuffields! I hope someone may be able to point me in the right direction.

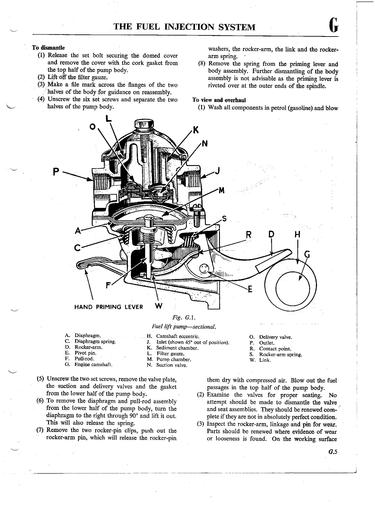

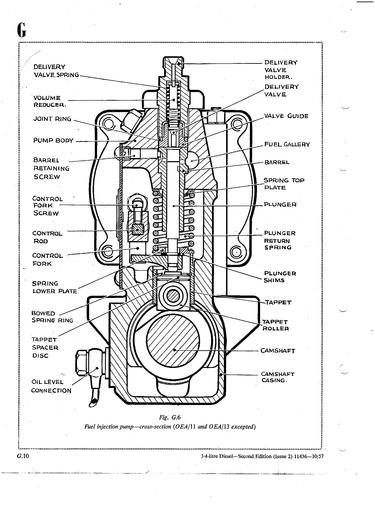

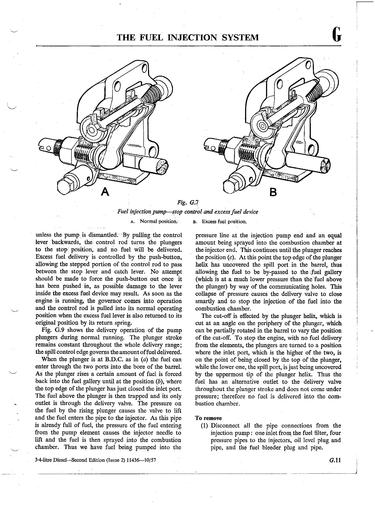

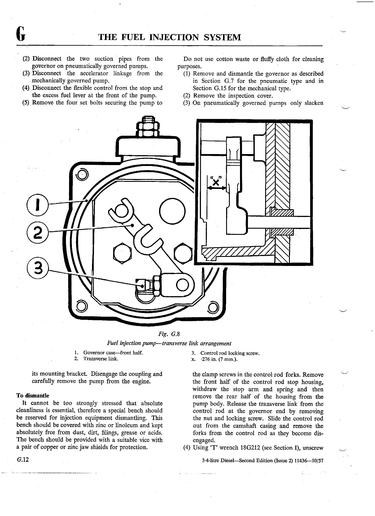

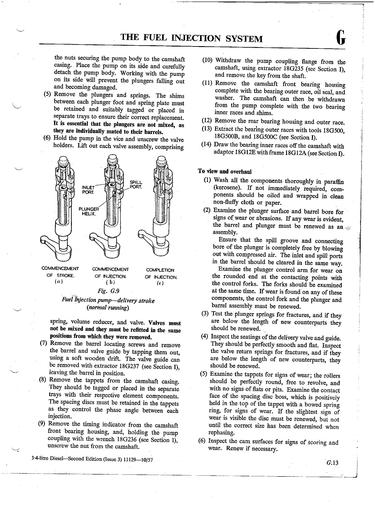

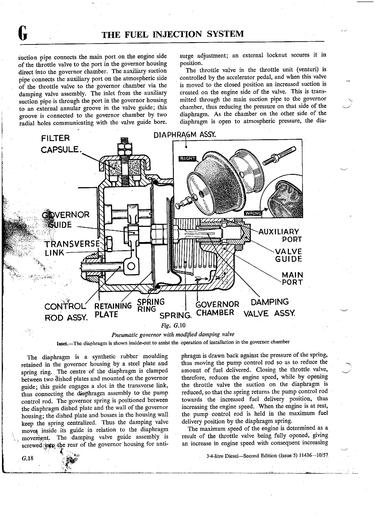

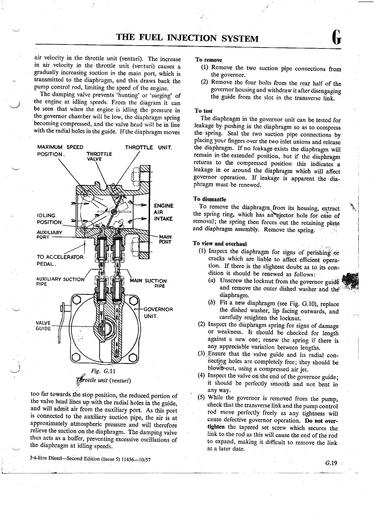

I have a Nuffield DM4 with BMC engine and Simms injector pump with diaphragm governor. The other day the motor revved ungoverned for a short time - probably 20 seconds but seemed much longer until I was able to shut it down! Traced the problem to a fractured diaphragm in the governor and replaced same. The diaphragm that came out was shaped like an open tin can but replaced it with a convoluted shaped one (a Nuffield/Simms replacement part) that a diesel repair centre would be fine. The rack operates freely and the cold start button sets OK.

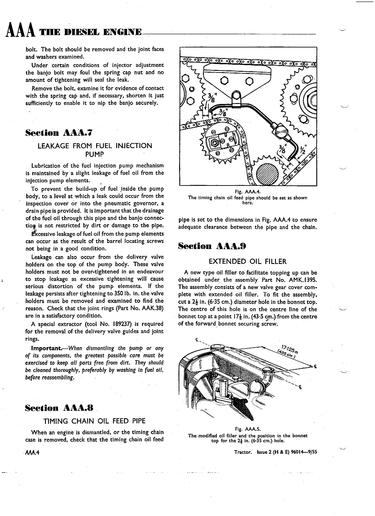

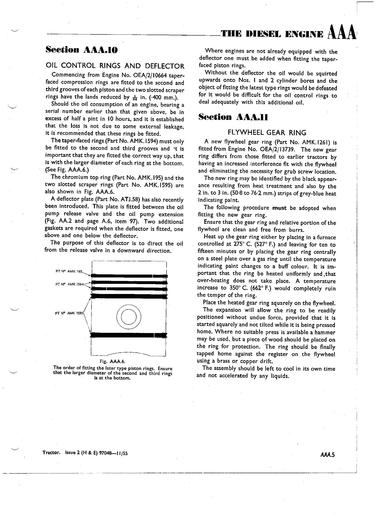

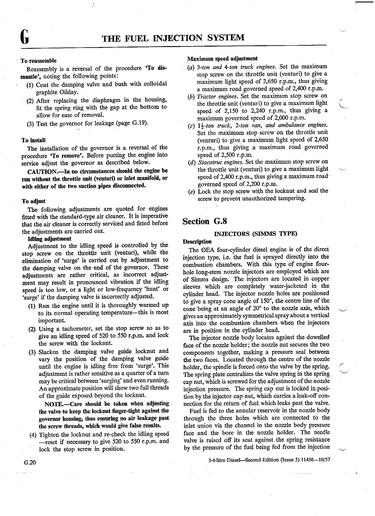

Problem is that when attempting to start it pours white smoke out the exhaust without any detectable firing in any cylinder.Can hear the injectors creaking when turning over by hand and each cylinder appears to have the same amount of compression -(by unscrewing the decompression bolts in the head). I thought maybe the timing may have changed with the over revving so pulled the timing cover off today to check. It appears to be OK according to the manual I have - 30 chain pitches between Injector pump drive and camshaft and 34 pitches between camshaft and crankshaft sprocket marks.I am thinking perhaps next step may be to remove the injectors to make sure they are atomising OK. When the over revving event occurred I had the exhaust off as I had been working on solenoid/battery and amongst the panic was aware of a lot of flame from the open exhaust.

Thanks for any help

Regards

Bill

Given your location David I thought you may have had something to do with Nuffields! I hope someone may be able to point me in the right direction.

I have a Nuffield DM4 with BMC engine and Simms injector pump with diaphragm governor. The other day the motor revved ungoverned for a short time - probably 20 seconds but seemed much longer until I was able to shut it down! Traced the problem to a fractured diaphragm in the governor and replaced same. The diaphragm that came out was shaped like an open tin can but replaced it with a convoluted shaped one (a Nuffield/Simms replacement part) that a diesel repair centre would be fine. The rack operates freely and the cold start button sets OK.

Problem is that when attempting to start it pours white smoke out the exhaust without any detectable firing in any cylinder.Can hear the injectors creaking when turning over by hand and each cylinder appears to have the same amount of compression -(by unscrewing the decompression bolts in the head). I thought maybe the timing may have changed with the over revving so pulled the timing cover off today to check. It appears to be OK according to the manual I have - 30 chain pitches between Injector pump drive and camshaft and 34 pitches between camshaft and crankshaft sprocket marks.I am thinking perhaps next step may be to remove the injectors to make sure they are atomising OK. When the over revving event occurred I had the exhaust off as I had been working on solenoid/battery and amongst the panic was aware of a lot of flame from the open exhaust.

Thanks for any help

Regards

Bill