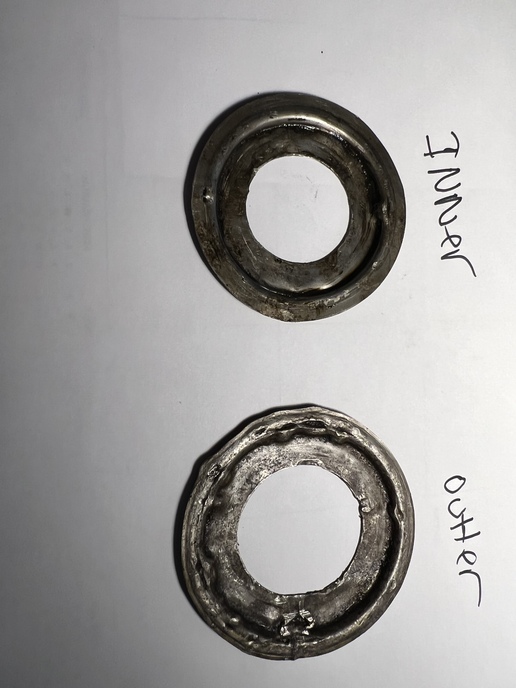

I was removing the the front wheel bearings race and found they have grease retainers. well they got messed up. Are they really needed ? i was going to order new one but they are way over priced. has any one run into this. I did hammer them back into shape , they might work. We have a whole fleet of school buses that run grease and they dont have grease retainers any thought? The outter retainer is$116.56 and the inner is $50.00 which is crazy for a little piece of steel.

This post was edited by busboy on 06/16/2023 at 04:27 am.

This post was edited by busboy on 06/16/2023 at 04:27 am.