Part 1

Hoping you can assist me with electronic distributor timing on a FE35 petrol

Firstly, had to make a brass insert of the Lucas coil as the new lead wouldnt fit.

Then bought No1 cyclinder to compression, felt by finger

The distributor rotor was pointing at No1

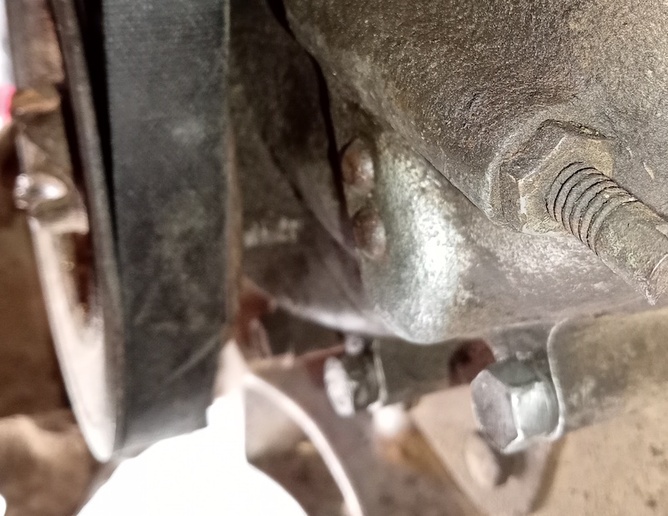

Removed the starter motor, inserted 1/4 dowell so 0 degrees timing mark was set

Then tightened distributor with the rotor centred on the magnetic trigger ring

I was going to use a timing light but tractor has new sleeves, pistons etc and hard to manually crank

So I refitted starter motor, it went first time, adjusted carby a little as plugs were ooty

Previously, carby was set at 1 turn on low and high, now 1.3/4 as per manual

Hoping you can assist me with electronic distributor timing on a FE35 petrol

Firstly, had to make a brass insert of the Lucas coil as the new lead wouldnt fit.

Then bought No1 cyclinder to compression, felt by finger

The distributor rotor was pointing at No1

Removed the starter motor, inserted 1/4 dowell so 0 degrees timing mark was set

Then tightened distributor with the rotor centred on the magnetic trigger ring

I was going to use a timing light but tractor has new sleeves, pistons etc and hard to manually crank

So I refitted starter motor, it went first time, adjusted carby a little as plugs were ooty

Previously, carby was set at 1 turn on low and high, now 1.3/4 as per manual