I inherited a Ford 600. Did these come in a 6 or 12v option when made? It has a 12v generator, 12v battery. 12v coil with built in resistor, but the ground is negative? I know nothing about the difference in 12 and 6v, but from what I’ve read 12v generators can be neg. ground? The issue I see is it has a very old regulator and I have no idea if it’s made for 12 or 6v - does

this matter? Anyway I can identify if it’s 12 or 6v regulator?

Welcome aboard the wonderful world of Ford Tractors. Do you have any prior experience with Ford Tractors? All are great workhorse machines and if you have any mechanical ability, and know how to turn a wrench correctly, are fun to work on (most times), and parts are still available for these 80+ year old machines. You have some incorrect information stated and need to stop doing anything til you know proper systems and procedures. 12V uses the NEG GRN setup for example. Another is no VR is used on a 12V Conversion. Still another is an external resistor is NOT wired unless you are using the OEM 6-V Coil. So, your wiring is incorrect out of the gate. Best to stop here. This is a long post but important vital information contained within. SAVE.

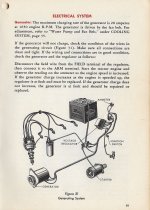

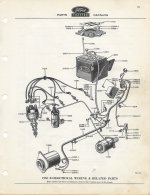

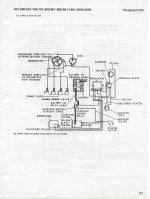

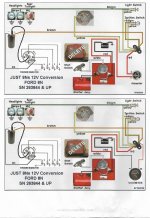

Your next step is to get copies of the ESSENTIAL MANUALS and read religiously. You must understand that all FORD Modules; cars, trucks, and tractors used the 6-VOLT/POSITIVE GROUND until the late 1950’s. The only exception is the 1943 Ford-Ferguson 2N Wartime Model with no electrics or rubber but that is another chapter to read later. In the late 1950’s FORD TRACTOR released the DIESEL MODELS and they all used a 12-VOLT/NEG GRN setup but still with a Voltage Regulator. Moden 12-Volt Conversions today use an ALTRENATOR, the DELCO 10-SI 1-Wire Unit is a proven reliable unit, and the VR is removed from the circuit altogether. You must understand the 6V/POS GRN system first before you go messing with a 12V conversion. Incorrect Wiring is the root cause of 99.98% of all non-starting and electrical issues regardless if 6V or 12. SEE WIRING DRAWINGS,

NOW, listen up. Avoid buying any new parts for now. How do you know if old are defective? Disconnect the battery. Take to a local shop and have tested under load. It must sustain specific gravity and a full charge under load. If poor or bad, replace with a GRP 1 for 6V or a GRP 35 for a 12V unit. Do not reconnect the new one until you verify entire wiring system is correct. Get a digital VOM and set it to Continuity. Do not use an idiot test light.

NOTE - OEM 6V/POS GRN setup uses:

3-WIRE/2-BRUSH, 20 AMP B-Circuit 6V GENERATOR with a belt tensioner.

3-WIRE Terminal VOLTAGE REGULATOR.

3-WIRE 6V STARTER MOTOR and uses a RELAY (SOLENOID).

30/30 AMMETER

Neutral Safety Start Pushbutton.

Angle Mounted (SIDE) Distributor. Another important chapter. Tune-up and timing set with timing light on flywheel thru side inspection cover. Firing Order is 1, 2, 4, 3 CW. SEE MANUALS.

There is NO Voltage Regulator sue in a 12-VOLT Conversion. It gets removed from the circuit.

There is NO resistor used in the wiring in the electrical system from 1952 on. There is a junction terminal block on the back of the dash – SEE DRAWING.

You only need an external 1.5 OHM resistor when using a 12V conversion and your OEM 6-V Coil. Eliminate it by swapping out to a verified 12V Coil.

After you get all wiring verified to be correct you can move on to prepping for the start-up. The side distributor is 2nd most misunderstood feature. READ MANALS.

You must use a Fan Belt Tensioning Bracket, regardless if using a GEN or an ALT. Without proper fan belt tension you will never charge the battery. Period. Poor belt tension also affects the cooling system and can cause water pump damage and overheating.

Lastly, when all is right with your system, you should consider investing in a good float charger (DELTRAN) to maintain the battery life at 100% when tractor is idle in the barn.

Start with the ESENTIAL MANUALS and related documents. Copy and paste this post and save it your PC for reference. Pictures can be also saved to your PC as well. Let us know on your progress as you learn more. Good Luck!

Tim Daley (MI)