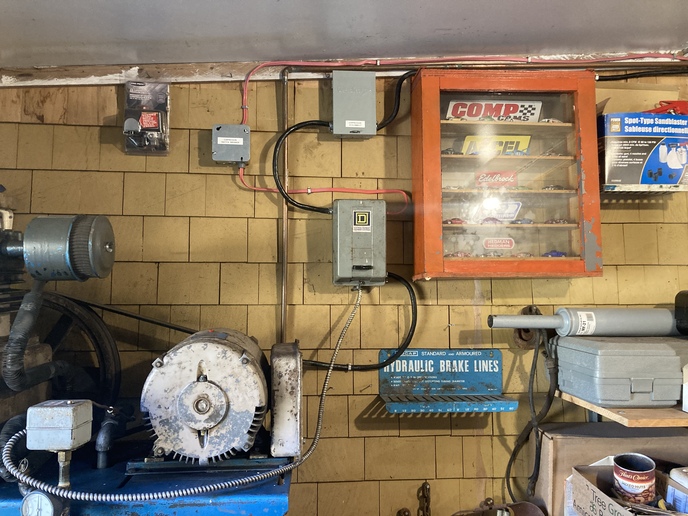

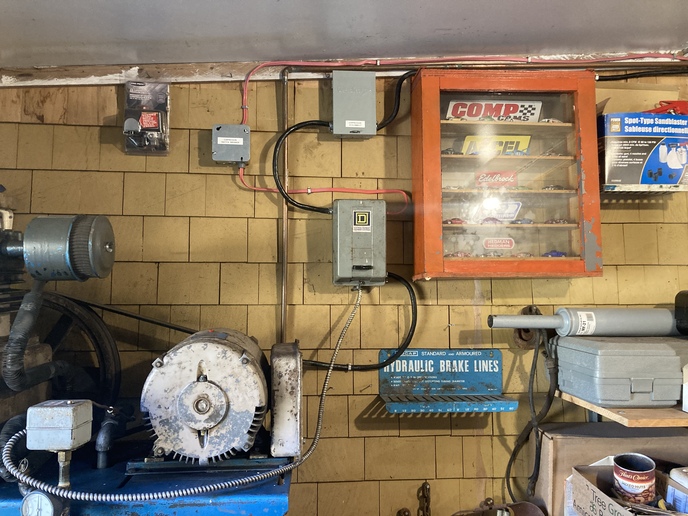

We were there awhile ago and my father in law asked me to see if I could figure out why the compressor wouldnt run. It had too small of wire fed through too small of a switch and kept overtime burning out the light switch that controlled it. Non electrical terms we ran heavier wire and a more suited shut off and rewired the control. For the electricians on here heres the rest of the story lol.

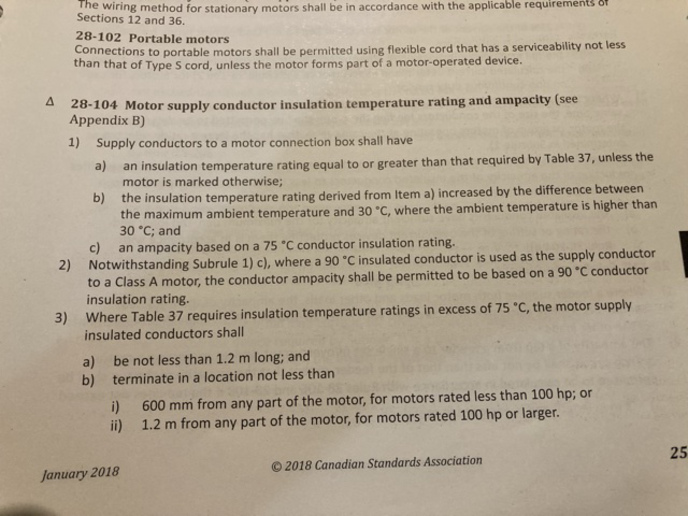

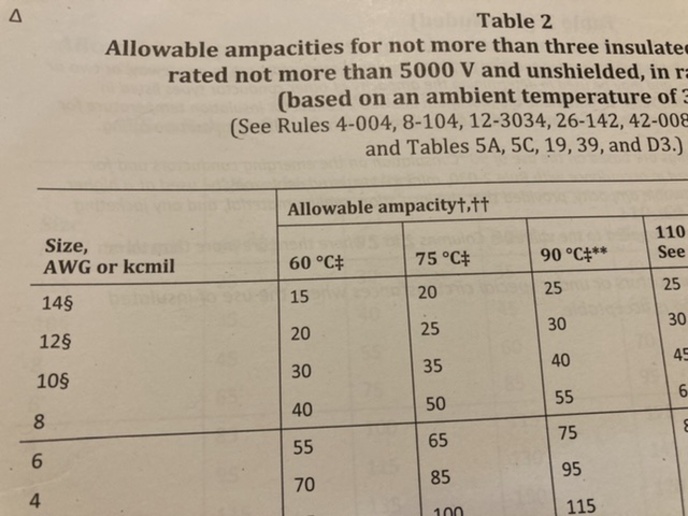

Its a 5hp motor with 25A FLA so we rewired most of the compressor circuit. I removed the 12/2 from sharing a 40A breaker with a feed for a separate building which fed a double pole 15A switch that fed L1&L2 at the motor starter then T1&T2 fed 14/2 BX that supplied L1&L2 at the motor. Theres #8 feeding the separate building but we refed it with a double pole 30A breaker as theres only a few outlets and lights in there. We ran #10 from the 40A breaker to a 50A HVAC style disconnect, then from there to the starter and also replaced the 14/2 BX with #10 to the motor. We rerouted the #12 that originally ran to the starter to a 4x4 JB , wirenutted one line together and fed the other through a 15A push button breaker. We used that circuit as a switch loop to break the control circuit fed through the pressure switch and a single pole switch by the door so he can still switch it off when hes not using it. Took a couple hours but its a way better arrangement.

Its a 5hp motor with 25A FLA so we rewired most of the compressor circuit. I removed the 12/2 from sharing a 40A breaker with a feed for a separate building which fed a double pole 15A switch that fed L1&L2 at the motor starter then T1&T2 fed 14/2 BX that supplied L1&L2 at the motor. Theres #8 feeding the separate building but we refed it with a double pole 30A breaker as theres only a few outlets and lights in there. We ran #10 from the 40A breaker to a 50A HVAC style disconnect, then from there to the starter and also replaced the 14/2 BX with #10 to the motor. We rerouted the #12 that originally ran to the starter to a 4x4 JB , wirenutted one line together and fed the other through a 15A push button breaker. We used that circuit as a switch loop to break the control circuit fed through the pressure switch and a single pole switch by the door so he can still switch it off when hes not using it. Took a couple hours but its a way better arrangement.