grandpa Love

Well-known Member

I put a ad on Facebook asking for 1-5

acres to cut and bale on shares. Just

something to use my tractors on. A couple

that we used to go to church with

contacted us about the 40 acres. They are

out of town until next week. They may not

even want all 40 cut. Wait and see I

guess. Also had a guy contact us about

cutting his 3-4 acres for $2 a bale.

Have several other offers for 50-50 split

on a couple acres. Definitely going to

talk to the folks with 40. It's close to

a couple friends of mine that do hay so

if I have a break down I might be able to

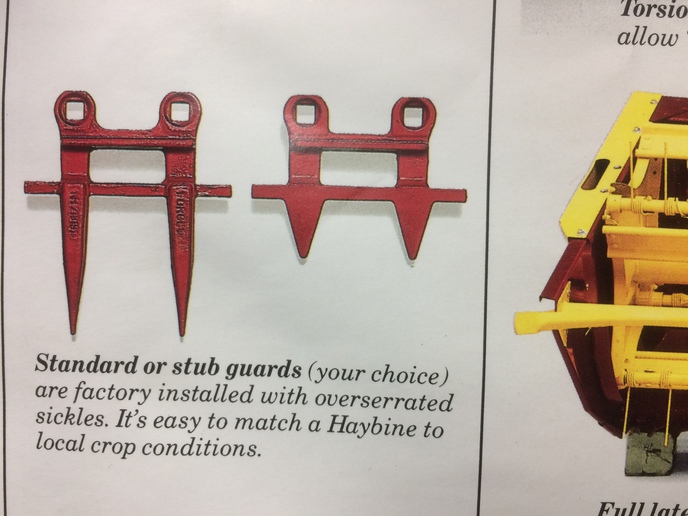

get some help! Thinking I will get that

haybine. Price is right. No hydraulics

on any tractor but I guess it could be

ratcheted up and down. It's a new

Holland.

acres to cut and bale on shares. Just

something to use my tractors on. A couple

that we used to go to church with

contacted us about the 40 acres. They are

out of town until next week. They may not

even want all 40 cut. Wait and see I

guess. Also had a guy contact us about

cutting his 3-4 acres for $2 a bale.

Have several other offers for 50-50 split

on a couple acres. Definitely going to

talk to the folks with 40. It's close to

a couple friends of mine that do hay so

if I have a break down I might be able to

get some help! Thinking I will get that

haybine. Price is right. No hydraulics

on any tractor but I guess it could be

ratcheted up and down. It's a new

Holland.