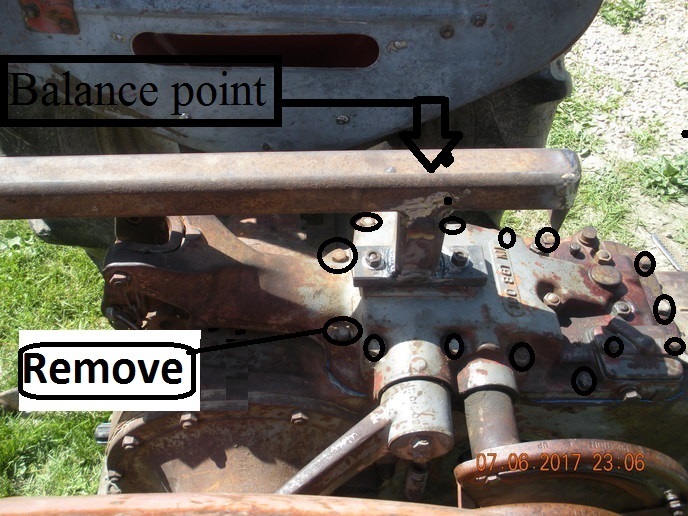

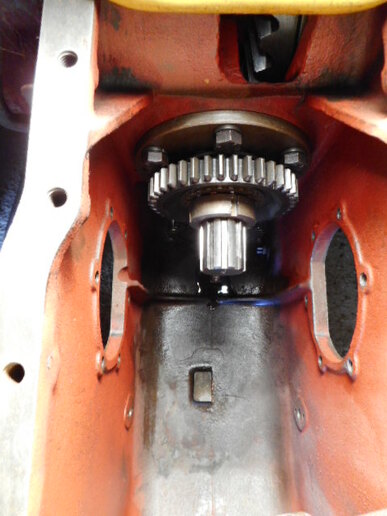

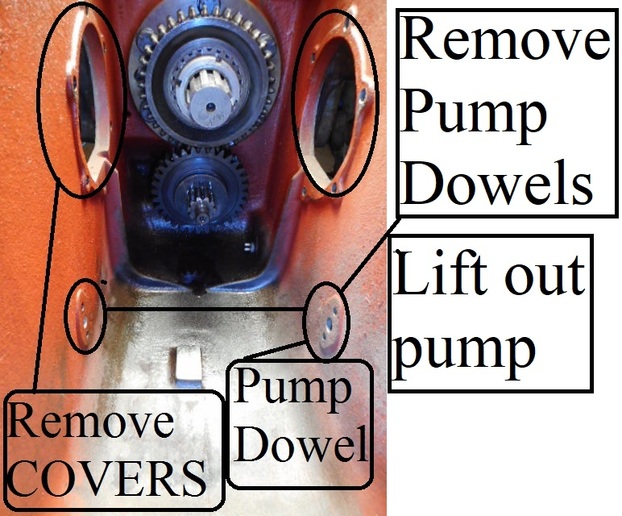

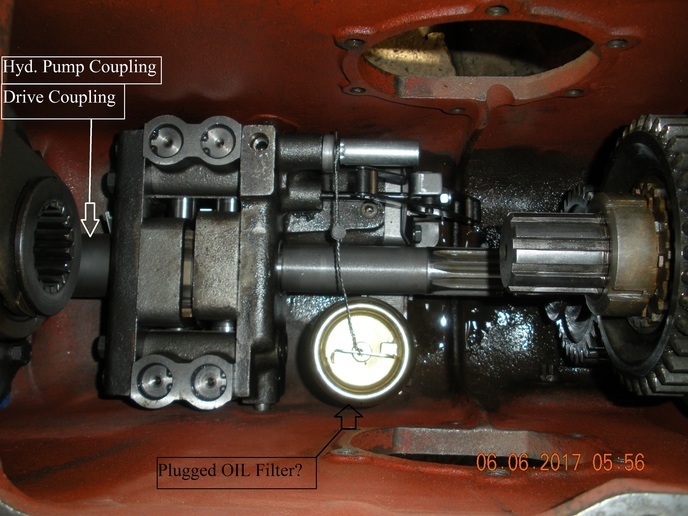

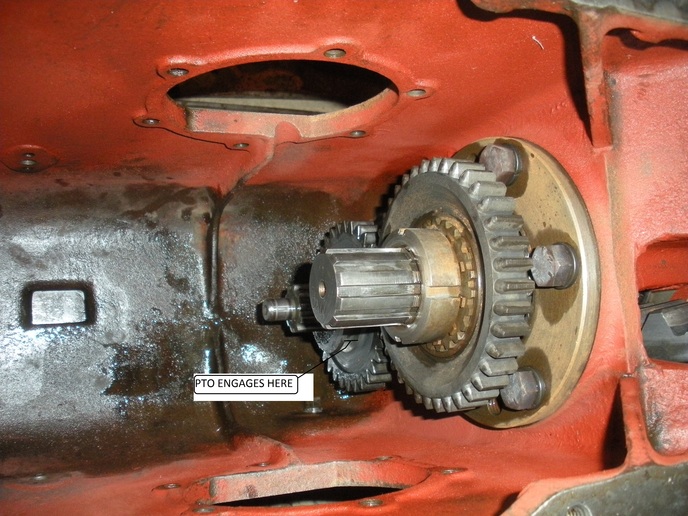

I'm working on a MF 40 tractor that the US navy had. It really is just the MF backhoe/loader since it has the automatic transmission in it. (Just doesn't have a backhoe or FEL) The internal Hyd pump wasn't working. So I've started taking it apart to repair. I've found the filter screen was half gone and the pump is full of what looks like wheel bearing grease. I figure while I have it apart, I'd like to add a PTO shaft to it. It looks like this tractor uses the same setup as most other MF from the period. But I'm trying to figure out how the hyd pump comes out. I've seen a post about the bullet that is in there supporting the back section of the pump. Does the tractor have to be split to get the pump out as well as that bullet? I think I see a bolt head on the backside of the bullet where the PTO shaft would be?

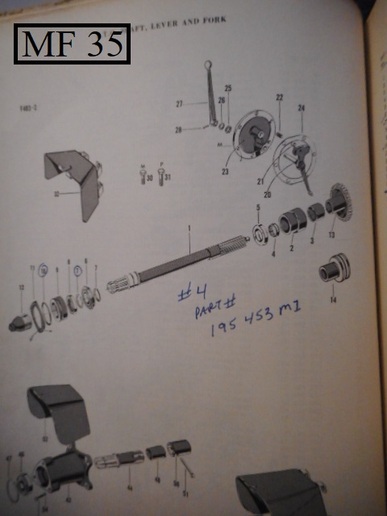

Next, to add the PTO shaft, I assume I just need the shaft, inner and outer bearings/seal/retainer. Then the selector off the side of the tractor and I suppose the gear?

Next, to add the PTO shaft, I assume I just need the shaft, inner and outer bearings/seal/retainer. Then the selector off the side of the tractor and I suppose the gear?