Tom in TN

Well-known Member

- Location

- Southern Middle Tennessee

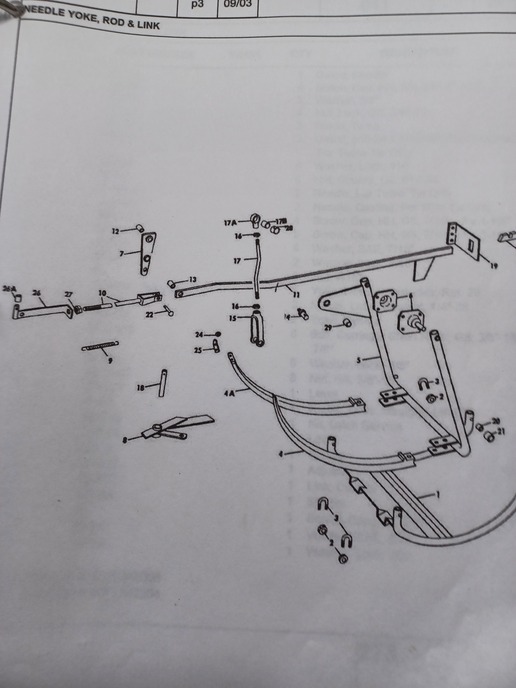

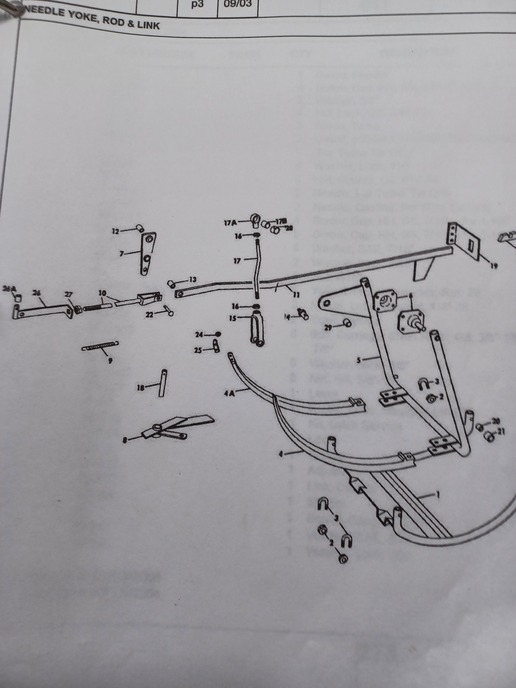

Here's a crappy picture from the NH 273 parts manual of the topic they call Needle Yoke, Rod and Link. My plunger stop wasn't working and I did serious damage to my baler. I'm trying to make sure that the plunger stop is now working. It was hanging up when it should have gone into the chamber. The two parts on the diagram are items number 8 and 18. I'm trying to remove #8, the Latch service kit from the baler. To do so, I think that I need to remove #18, the pin that the latch pivots around. There's a cotter pin that goes through the Latch service kit and the pin. I've removed that cotter pin, but I can't get the Latch out of the baler.

The cotter pin goes through a sleeve that appears to be an integral part of the latch and then through the pin. That sleeve will not rotate, consequently, the latch will not go into the chamber to stop the plunger.

Any ideas?

Thanks.

Tom in TN