Good day charisma1986

Before I started changing the point of ignition, I checked the condition of the Timing chain, and associate sprockets.

They were totally worn out!! Not uncommon with the Standard Engines in the TEA-20's.

At the end of a 12 inch ratchet I noticed the ratchet would move 2>3 between Clockwise and counter clockwise before

the rotor would move.

On my second TEA 20 S#251562 the drive TANG on the end of the DISTRIBUTOR shaft was so badly worn it would misfire.

The DRIVE TANG on the end of the DISTRIBUTOR on all three of my TEA -20's is OFF CENTER. The drive key way on the GEAR

DRIVE matting with the CAMSHAFT is also off center.

When my TEA 20 acted up, I placed a socket on the head of the CAP SCREW, that holds the pulley to the CRANKSHAFT .

I then turned the crankshaft Clockwise until the rotor (remove distributor cap and view rotor)started to move. I then

turned the crankshaft counter clockwise until the rotor started to move and found that the TIMING chain, and both the CAM

sprocket and Crank sprocket had to be replaced. Once I opened up the front cover, the GOVERNOR assembly also had to be

replaced.

WITH BATTERY Disconnected..

ON both of my TEA-20s

I set the ignition timing by turning the engine over in the diction of NORMAL RUNNING /operating .... As the piston

approached TDC, there is a 1/4??? hole drilled through the engine bellhousing just below the Starter.

Inset an appropriate tool ( eg DRILL BIT shank) and when the matting hole in the flywheel aligns inset DRILL SHANK into

flywheel.

Rotate distributor rotor in direction that ROTOR turns when engine is running.

Take NOTE.. when Distributor POINTS JUST start to open secure distributor in place.

NOT ALL TEA-20's are static timed to the same point BTDC.

After I had the engine running (with starter removed) I then used a strobe light to advance the ignition until it would kick back on the hand crank. Then I retarded the ignition by ONE and a HALF teeth on the flywheel.

I'm away from my summer residence for several months, and do not have my FERGUSON ORIGINAL SERVICE MANUL with me.

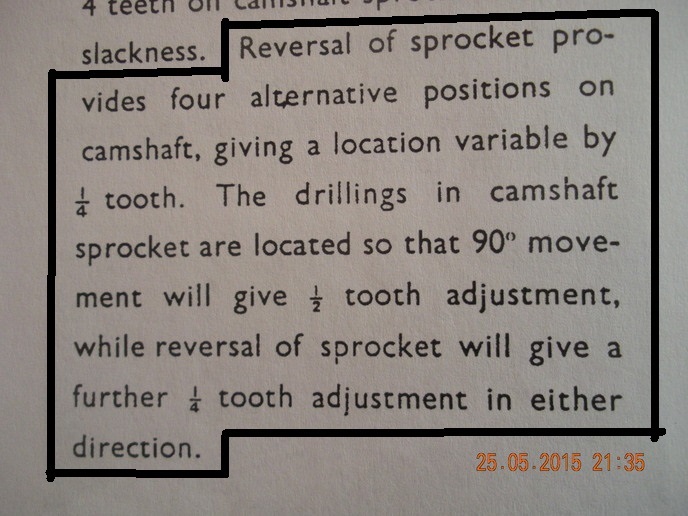

Info I compiled when REPLACING Crank sprocket ,Cam sprocket and Timing Chain.

(1) 85 MM Bore Engine:

(2) Front Lip Oil Seal National /Federal Mogul Lip Seal # 472164V A SMALL amount of BLUE Silicone was placed around the

inside bore of the front timing chain cover before Lip seal was installed:

(3) I installed a repair SLEEVE on the front drive Pulley, make DURA SLEEVE # 99175. The sealing area were the LIP SEAL

makes contact was slightly grooved. Dura Sleeve specs. 1.745>1.753 Diam. # 68 Rockwell Hardness:

(4) On installation the Governor plunger shall be reseeded tight against the Flyweights and no weights shall be loose or

hanging down:

(5) A small amount (only enough to make the surface shiny) of engine oil was added to the shaft of the governor PLUNGER as

well as the timing chain:

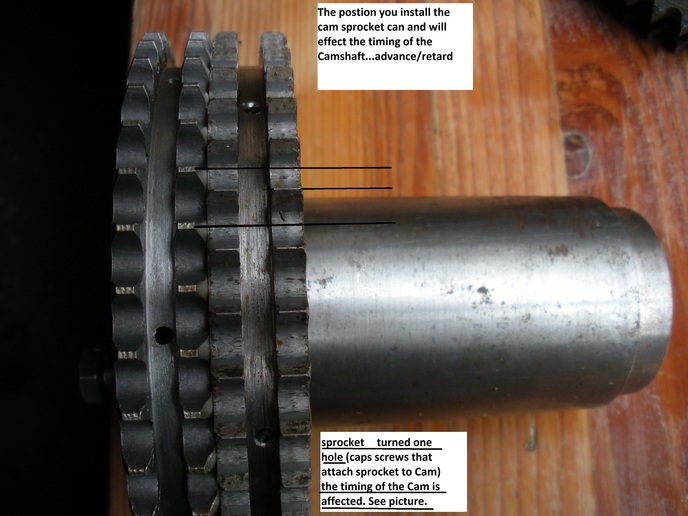

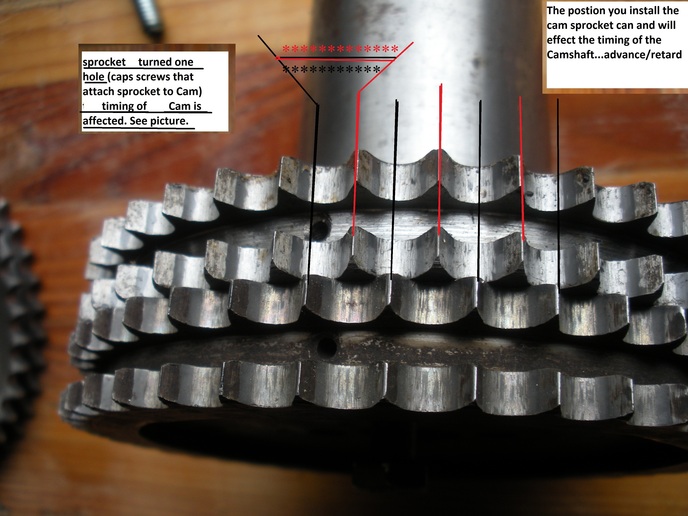

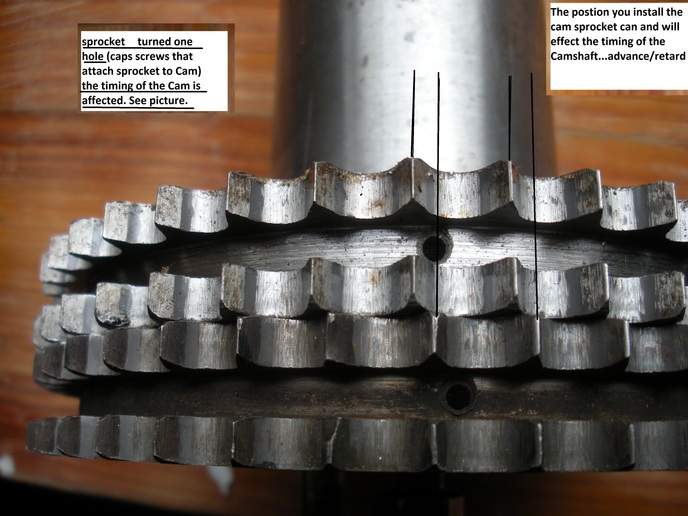

(6)There are NO timing MARKS on the NEW Sprockets. You may wish to line the timing marks up (facing each other) before you

remove the sprockets:

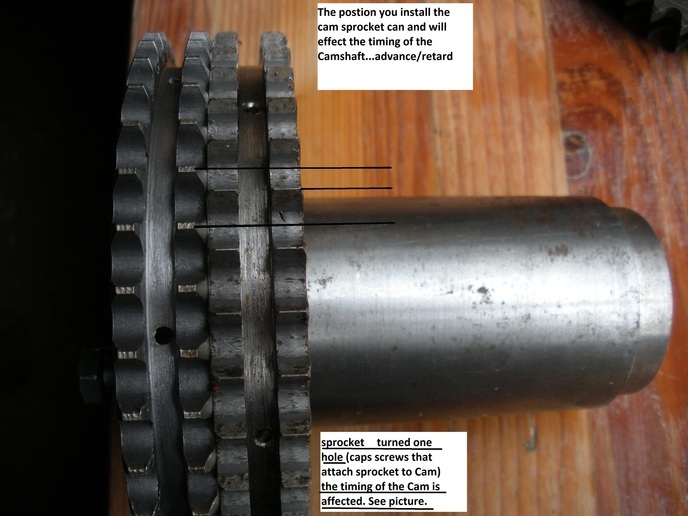

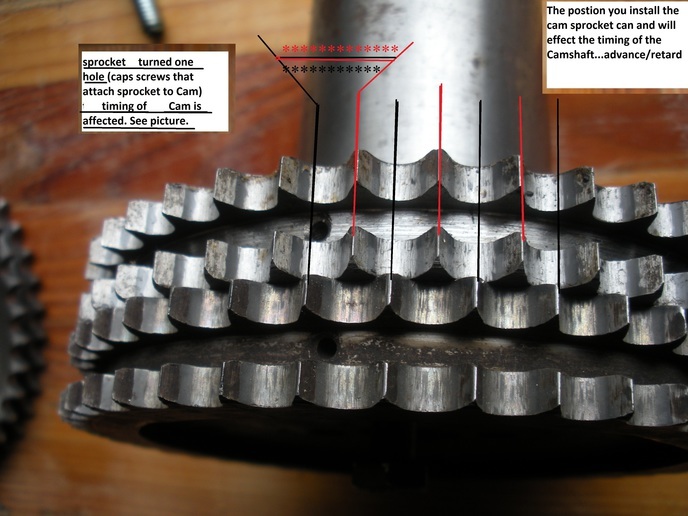

(7)Place the old sprocket (CAM SPROCKET) on top of the new sprockets and accurately scribe the new sprockets as to the

timing marks. There are FOUR holes in the hub of the CAM SPROCKET. Keep turning the old sprocket until the four holes and

all teeth line up. These holes are slightly off set. I used several SHOULDERED cap screws to ensure I had the new and old

sprockets properly aligned. You may have to flip the old sprocket over...see right up:

(8) It's good practice to measure the thickness of the hub of the old crankshaft sprocket and the new crankshaft sprocket

as the teeth on the two sprockets should align for both proper operation and longevity.(there were shims between the old

Crankshaft sprocket and the shoulder portion of the crankshaft):

Cheers

Bob...

Consider typing TEA20 Back to life in archives of this forum under the FERGUSON section and read all comments from

Griz/Bob (Aust)John(UK) and Tucker101

These gentleman seem to have a great handle on the TEA-20's There are several gentleman from the UK,Ireland,Australia and

the USA with more experience than I have...