Good news first. I went and purchased another multimeter that will test diodes. I tested all four diodes and on all four I get current in one direction only. Readings range from 470 on the lowest to 477

on the highest. On two I get readings with the red lead on the diode and the black lead on the tail. On the other two I get readings with the red lead on the tail and the black lead on the diode. In the

opposite direction for each diode there is no reading on the multimeter.

The bad news. While working on it I discovered the item (safety capacitor?) in the picture below laying in the bottom of the diode bridge. The numbers on it are V150R-6. It appears that the solders broke

connecting the capacitor to the jumper wire and I need to solder it back on. The capacitor does not appear to be burnt or damaged.

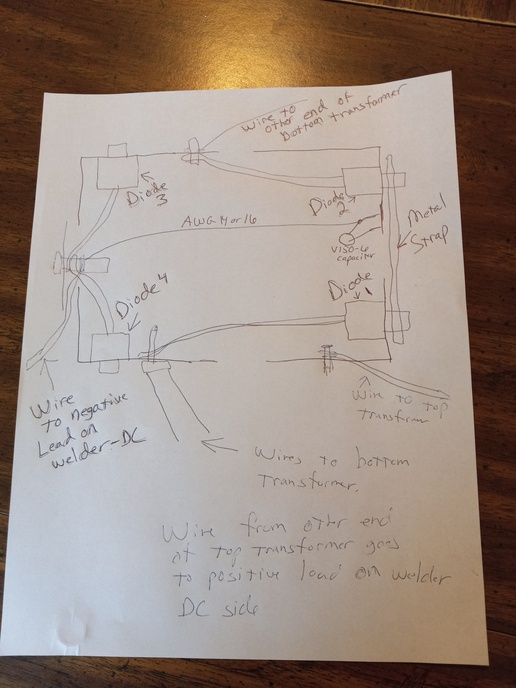

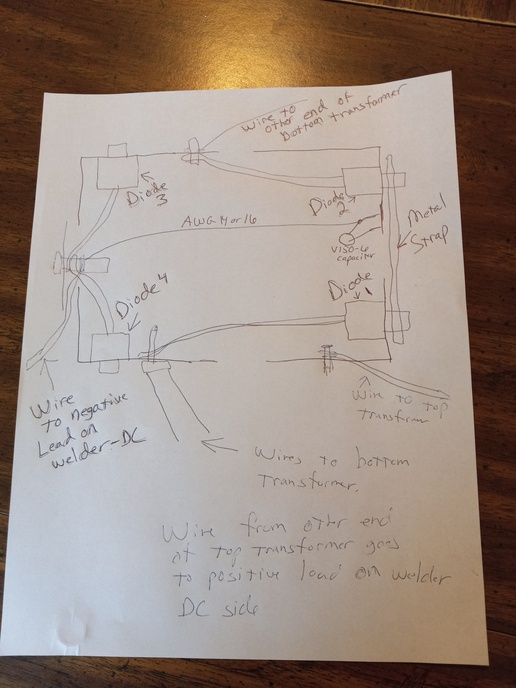

The diode bridge on this welder consists of four metal aluminum angles electrically insulated from each other. The welder fan is mounted in middle of the angles. I've drawn a picture of how the diodes are

mounted and tried to label things on it. There is a jumper wire (probably 14 or 16 AWG size) that runs from the plate that diode 2 is mounted to over to the bolt connector that the diode tails of the number

3 and 4 diodes are connected to. This capacitor appears to have been soldered from the jumper wire to the metal plate for diode 2.

From the diagram, diodes 1 and 2 are electrically connected via a metal strap. The tails for diodes 1 and 2 connect to the plates that diodes 3 and 4 are connected to. The tails for diodes 3 and 4 connect

to a common connector that then goes to the welder DC negative lead. The two wires that broke are the two wires labeled as wires to bottom transformer. These wires are connected to the metal plate where

diode 4 is mounted as well as the tail for diode 1.

I hope this makes sense.

I am thinking the jumper wire running from the diode 2 metal plate over to the common connector for the tails of diodes 3 and 4 with the capacitor is a safety mechanism.

on the highest. On two I get readings with the red lead on the diode and the black lead on the tail. On the other two I get readings with the red lead on the tail and the black lead on the diode. In the

opposite direction for each diode there is no reading on the multimeter.

The bad news. While working on it I discovered the item (safety capacitor?) in the picture below laying in the bottom of the diode bridge. The numbers on it are V150R-6. It appears that the solders broke

connecting the capacitor to the jumper wire and I need to solder it back on. The capacitor does not appear to be burnt or damaged.

The diode bridge on this welder consists of four metal aluminum angles electrically insulated from each other. The welder fan is mounted in middle of the angles. I've drawn a picture of how the diodes are

mounted and tried to label things on it. There is a jumper wire (probably 14 or 16 AWG size) that runs from the plate that diode 2 is mounted to over to the bolt connector that the diode tails of the number

3 and 4 diodes are connected to. This capacitor appears to have been soldered from the jumper wire to the metal plate for diode 2.

From the diagram, diodes 1 and 2 are electrically connected via a metal strap. The tails for diodes 1 and 2 connect to the plates that diodes 3 and 4 are connected to. The tails for diodes 3 and 4 connect

to a common connector that then goes to the welder DC negative lead. The two wires that broke are the two wires labeled as wires to bottom transformer. These wires are connected to the metal plate where

diode 4 is mounted as well as the tail for diode 1.

I hope this makes sense.

I am thinking the jumper wire running from the diode 2 metal plate over to the common connector for the tails of diodes 3 and 4 with the capacitor is a safety mechanism.