Ken Christopherson

Well-known Member

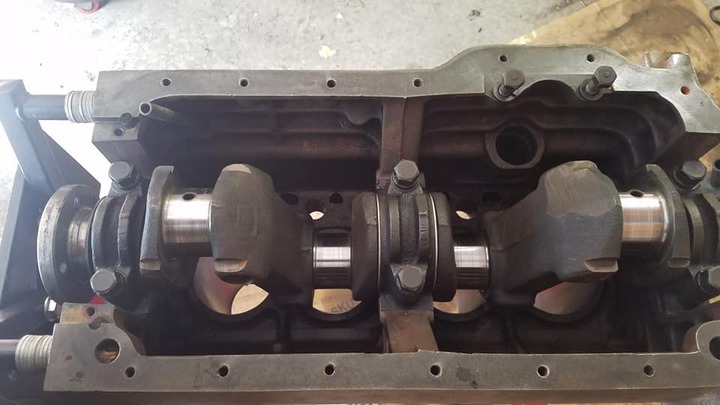

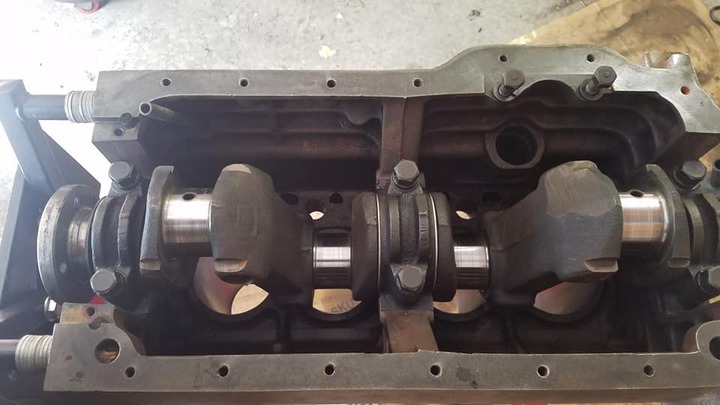

Hello all! Well, I finally got around to getting some more work done on the 1942 Farmall H memorial restoration project. Started getting the sleeves, pistons, bearings, etc. installed in the block. Sure is going together well. I'm still searching for a few more parts (battery box, rear rims I am waiting to hear on)... But once all that stuff comes in it is just more parts cleaning, lots of seals and gaskets getting replaced, and then it is off for sandblast, prime, and paint. I have some special touches getting added to this project to really set it off from others, and I hope you all like that. I won't spoil the surprise, though! I have to give a big thanks to Titan Tires for sponsoring, JR's Custom Plating, as well as many, MANY donors for either contributing to the GoFundMe or donating parts that I am in need of. The end goal is to take whatever funds are left and donate them to the SAVE organization. The tractor will be used to travel from show to show, plow days, and parades to help raise awareness for suicide and mental health. Included are some photos of where we are at so far, and also a link to the video series on the project.

I hope you all like the progress so far. She sure will be a good looking machine!

Reassembly Video 1

I hope you all like the progress so far. She sure will be a good looking machine!

Reassembly Video 1