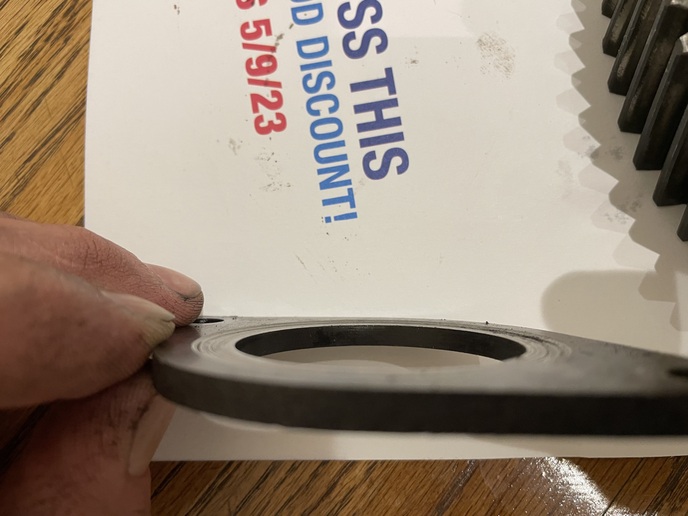

I got the parts all back from the machine shop for my 7610, and started to get the new cam in place, but I checked the gap between the gear

and thrust plate and found I have 0.027 of clearance. Upon disassembly, the thrust plate has significant wear (appears to be about 0.012-

0.014 of wear from best I could measure with a set of calipers) and the gear has some light grooving to the face to contacts the thrust

plate. Couple questions:

1) Can the thrust plate be reversed for more life? The OD of the cam is larger than the gear, so it rides outside of the worn area.

2) Would a new thrust plate be enough? If my measurements are close, I would be 0.009-0.007 of endplay with a flat thrust plate, which is

the high end/just out of tolerance. Or do I need to shop for a new gear? Looking at pictures of used gears, it looks like the side of the

gear in the picture is supposed to be very smooth.

3) Is this a sign of something else? This is the engine's 2nd complete overhaul, and the cam was starting to show pitting on the leading

edges of the lobes. Also had 2 spun wrist pins. I believe they got the motor hot and that was what did it in this time around.

-Hurst

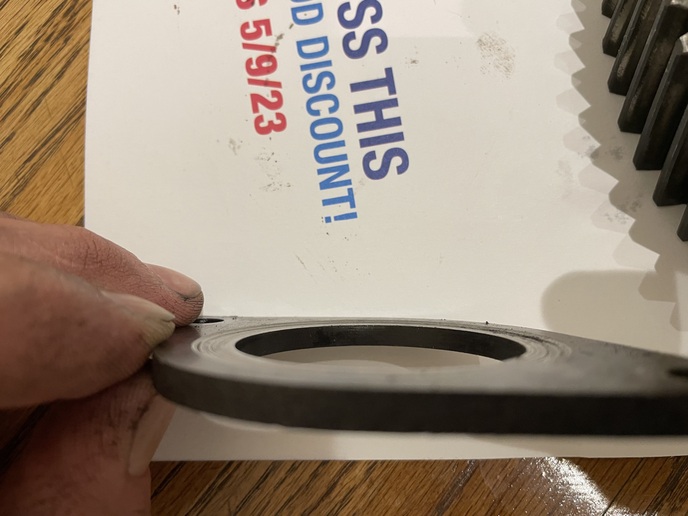

and thrust plate and found I have 0.027 of clearance. Upon disassembly, the thrust plate has significant wear (appears to be about 0.012-

0.014 of wear from best I could measure with a set of calipers) and the gear has some light grooving to the face to contacts the thrust

plate. Couple questions:

1) Can the thrust plate be reversed for more life? The OD of the cam is larger than the gear, so it rides outside of the worn area.

2) Would a new thrust plate be enough? If my measurements are close, I would be 0.009-0.007 of endplay with a flat thrust plate, which is

the high end/just out of tolerance. Or do I need to shop for a new gear? Looking at pictures of used gears, it looks like the side of the

gear in the picture is supposed to be very smooth.

3) Is this a sign of something else? This is the engine's 2nd complete overhaul, and the cam was starting to show pitting on the leading

edges of the lobes. Also had 2 spun wrist pins. I believe they got the motor hot and that was what did it in this time around.

-Hurst