Hemmjo

Member

In a previous thread we discussed how to install the plug on the back of the block that is partially blocked by the transmission. I recently completed that task without splitting the tractor.

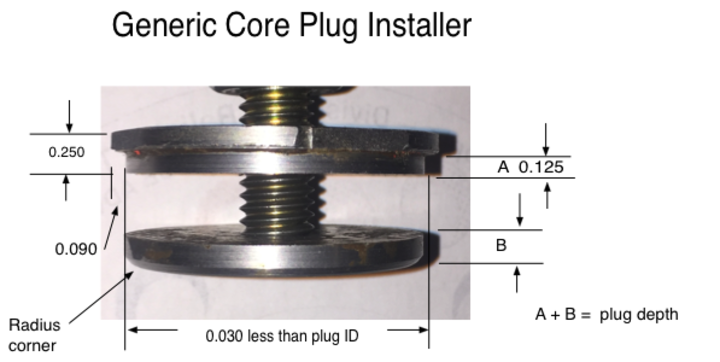

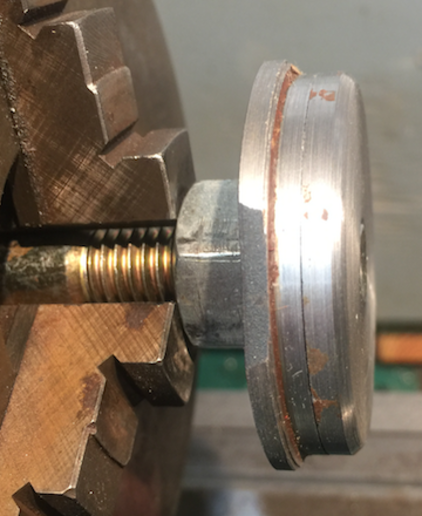

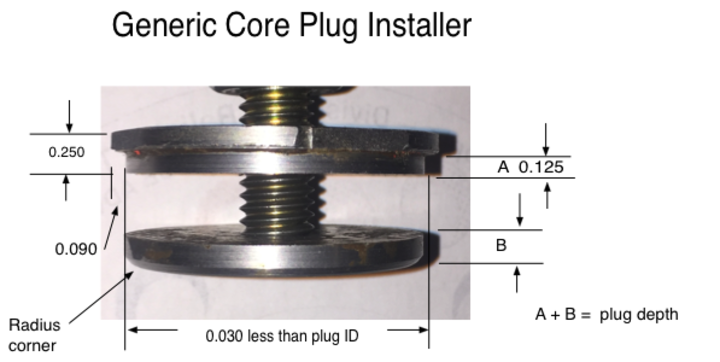

I turned 1/4 steel bar to proper size. I made the driver in 2 pieces so it would not be so thick. One piece fits into the plug, then you can use a pry bar to get it started. Then switch to the other piece which engages the rim of the plug to finish prying and hammering to seat the plug. This second piece also prevents the plug from being pushed in too far. It was quicker, and more fun for me, to make the tool than to split the tractor.

Photos below show the steps and the installer. The installer is also used to install the easy plugs by assembling the plates to the bolt.

I turned 1/4 steel bar to proper size. I made the driver in 2 pieces so it would not be so thick. One piece fits into the plug, then you can use a pry bar to get it started. Then switch to the other piece which engages the rim of the plug to finish prying and hammering to seat the plug. This second piece also prevents the plug from being pushed in too far. It was quicker, and more fun for me, to make the tool than to split the tractor.

Photos below show the steps and the installer. The installer is also used to install the easy plugs by assembling the plates to the bolt.