Good evening, all

This seemed like a pretty straight forward process but I obviously buggered something. Hydraulics were fine before replacing the busted plunger. I ran it for probably at least a year with a pair of Vice Grips holding the old plunger stub out a ways just so the lift would work.

Thinking back over it now, there are a couple details that seem like they could have contributed to this issue:

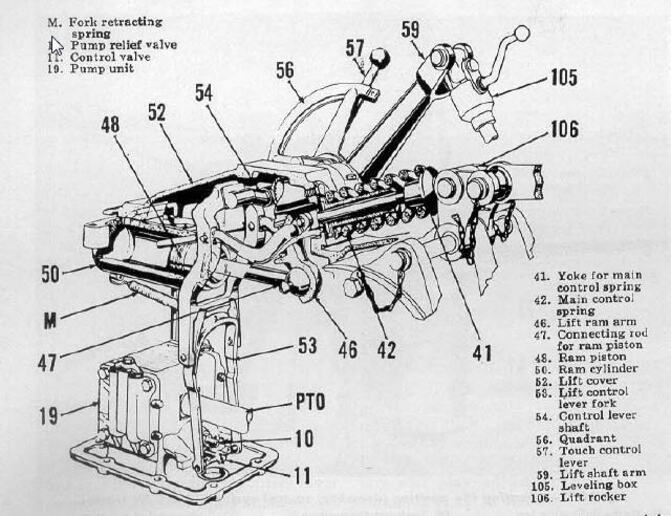

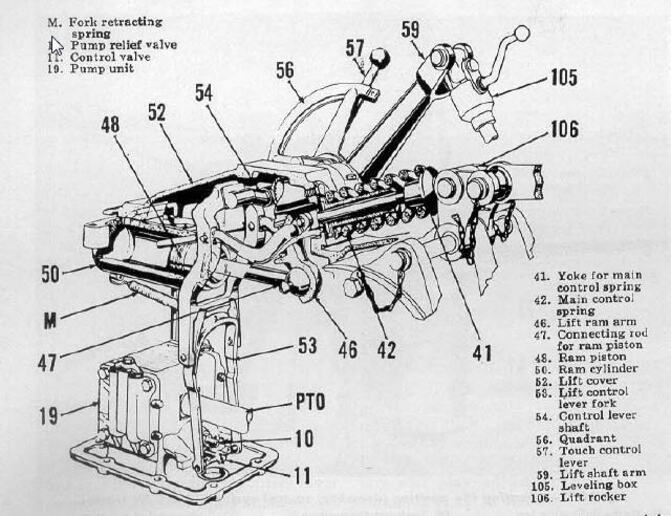

1) the lift was lowered when I removed the top cover. When putting it back on, I know I flipped the lift shaft arms (#59 in diagram below) up to what would have been the raised position. Maybe the connecting rod (#47 in diagram below) came out of place?

2) at one point prior to reinstalling the control spring and yoke, I leaned on the draft plunger and it popped back in a few inches. Would this have dislodged something?

I think the worst part of this job was getting that darn T for the hydraulic exhaust valve back into the fork. Wow! It was a struggle to my arm in there!

This seemed like a pretty straight forward process but I obviously buggered something. Hydraulics were fine before replacing the busted plunger. I ran it for probably at least a year with a pair of Vice Grips holding the old plunger stub out a ways just so the lift would work.

Thinking back over it now, there are a couple details that seem like they could have contributed to this issue:

1) the lift was lowered when I removed the top cover. When putting it back on, I know I flipped the lift shaft arms (#59 in diagram below) up to what would have been the raised position. Maybe the connecting rod (#47 in diagram below) came out of place?

2) at one point prior to reinstalling the control spring and yoke, I leaned on the draft plunger and it popped back in a few inches. Would this have dislodged something?

I think the worst part of this job was getting that darn T for the hydraulic exhaust valve back into the fork. Wow! It was a struggle to my arm in there!