FarmerBlair

Member

Hi, I have a Ford 4000 and trying to rig up sway chains for the 3point. It didn't have the original setup up, and last year salvaged and restored a couple adjustable length lower lift arms. The rear axle adapters I picked up aftermarket.

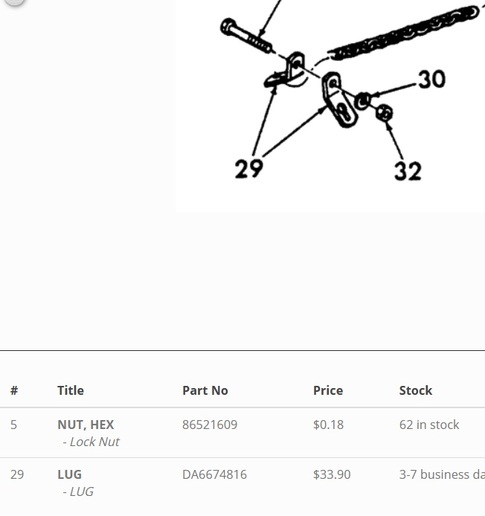

The lower lift arms have a 7/8" nub for attaching something via a linchpin (not sure what). Last year I had cut and formed a couple steel sway bars to fit, and rigged up a way to bolt to the axle brackets, but was a real pain to hook it all up and not quite right. So I want to use a chain and turnbuckle system instead. Pics show lift arm and turnbuckle hanging from axle bracket.

My question is is there an adapter of some sort that will attach a chain link to that nub on the lower lift arm and be held in place using a linch pin? If not, thinking I can cut several inches off my sway bar that already has a hole drilled for the nub, and then drill a new hole for attaching a chain. If there were some link designed for that purpose, I would just buy it. That 7/8" nub on the lift arm is pretty oversized though.

Thank you.

The lower lift arms have a 7/8" nub for attaching something via a linchpin (not sure what). Last year I had cut and formed a couple steel sway bars to fit, and rigged up a way to bolt to the axle brackets, but was a real pain to hook it all up and not quite right. So I want to use a chain and turnbuckle system instead. Pics show lift arm and turnbuckle hanging from axle bracket.

My question is is there an adapter of some sort that will attach a chain link to that nub on the lower lift arm and be held in place using a linch pin? If not, thinking I can cut several inches off my sway bar that already has a hole drilled for the nub, and then drill a new hole for attaching a chain. If there were some link designed for that purpose, I would just buy it. That 7/8" nub on the lift arm is pretty oversized though.

Thank you.