super99

Well-known Member

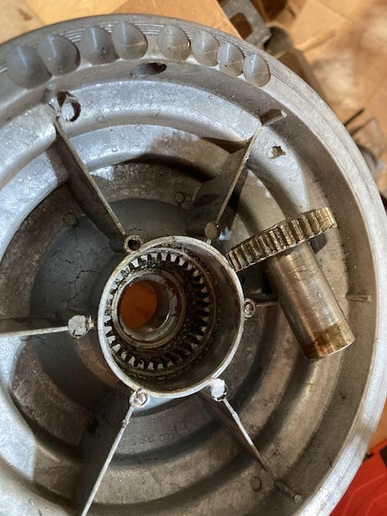

I got a little bit done before I ran out of energy. The driven pulley did have 3 screws in it, 2 are broke off flush and the threads are boogered on the other one

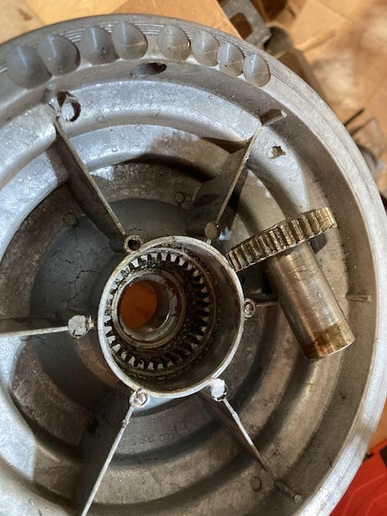

Next I started trying to get the bearing off. I was able to raise it some with small pry bars to get a puller on it. Instead of the bearing coming off, it is pulling the sleave the bearing is on out. Parts list is confusing on this. I have to hold the chuck so it doesnt turn while tightening the puller plus holding the puller from turning while tightening the puller. I dont have enough hands to hold everything.

Im wondering if I should remove the spindle and then try to get the bearing off but then I wont have anything for the puller to work against. Ideas or suggestions? Im beat for now, gotta rest up before trying something else. Thanks, Chris

Next I started trying to get the bearing off. I was able to raise it some with small pry bars to get a puller on it. Instead of the bearing coming off, it is pulling the sleave the bearing is on out. Parts list is confusing on this. I have to hold the chuck so it doesnt turn while tightening the puller plus holding the puller from turning while tightening the puller. I dont have enough hands to hold everything.

Im wondering if I should remove the spindle and then try to get the bearing off but then I wont have anything for the puller to work against. Ideas or suggestions? Im beat for now, gotta rest up before trying something else. Thanks, Chris