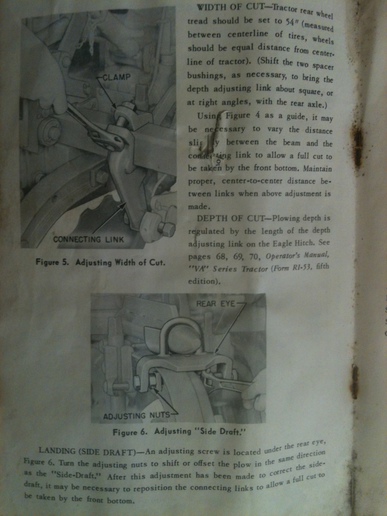

I still hope to find a 2 bottom eagle hitch plow in the future. I am no expert on plows or plowing. We had a 3-16 Case pull type on the farm and dad did most of the plowing while I did the milking. I see these plows with a turnbuckle type brace and some with hydraulic rams. What is the purpose of the turnbuckle. Does the hydraulic cylinder to make it bite into the ground better? I have a Ford plow for my VAC and it seems the geometry is quite a bit different. I always have trouble with the rear bottom going in deep enough, even though I have it set per the manual and have the middle arm short so the points bite.

Thanks for any info. Something to discuss while some of us are cooped up.

Thanks for any info. Something to discuss while some of us are cooped up.