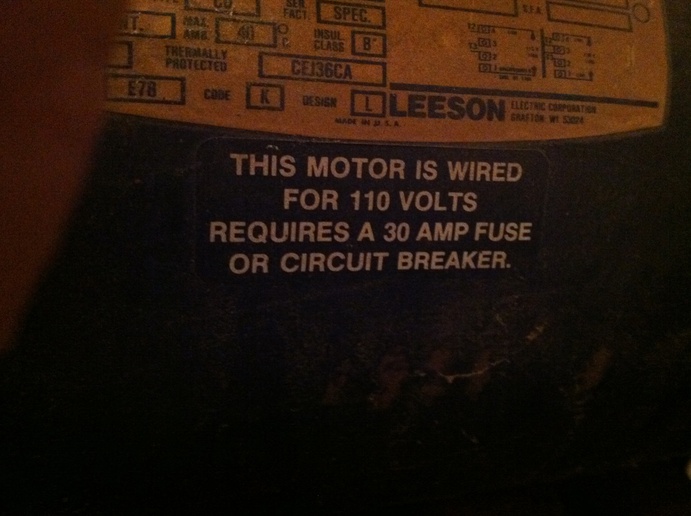

OKAY first of all I would advise you to reconnect the motor leads to run it at 240 instead of 120 volts BUT EITHER WILL STILL WORK.

1) EITHER 120 or 240 will require 3 wires, for 120 its a Hot/Black a Neutral/White and an Equipment Ground/Green or Bare,,,,,,for 240 its 2 Hots/Black and Red and an Equipment Ground Green or Bare.

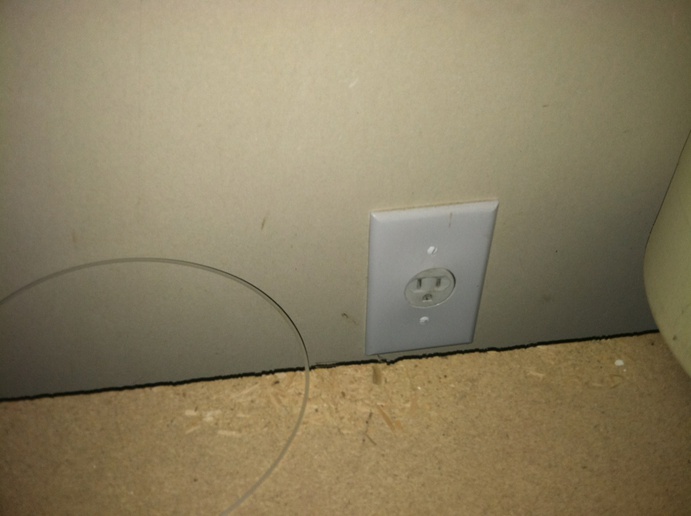

2) The motor should have a disconnection means in sight within 50 feet and a receptacle and cord with plug will suffice for that.

3) If you stay at 120 volts, you need a 120 volt 30 amp female receptacle and a matching 120 volt 30 amp male plug. (Any electrical supply house can provide both and many RV plugs and receptacles use a 120 volt 30 amp arrangement easily available at RV supply houses)

4) A 120 volt set up will require three 10 Gauge conductors from the panel to the receptacle and a 10 gauge flexible rubber etc cord with plug from the compressor to the receptacle.

5) A 120 volt set up will require a 30 amp single pole 120 volt circuit breaker and if such doesnt allow the motor to start up without tripping breaker you could use a 40 amp breaker

6) A 240 volt set up will require three 12 gauge conductors,,,,,,,,a 240 volt 20 amp 3 prong (2 hots & ground) receptacle,,,,,,,,a matching 240 volt 20 amp 3 prong plug,,,,,three 12 gauge conductors from panel to receptacle,,,,,,,,a 20 amp 240 volt two pole circuit breaker,,,,,,,,if that doesnt allow motor to start you can use a 30 amp 240 volt two pole circuit breaker

7) The motor should have thermal overload protection, such may be built in with a usually red resettable circuit breaker,,,,,,or external thermal overload protectors (heaters)

THAT ALL BEING SAID while a receptacle and cord with plug will suffice as a motor disconnecting means ID USE A WALL MOUNTED BLADE TYPE SAFETY SWITCH OR A WALL MOUNTED FUZED SAFETY SWITCH OR EVEN A COMBINATION STARTER A (IF THERES NO INTERNAL THERMAL OKVERLOAD PROTECTION). NOTE if you use a wall mounted fuzed safety switch you can use dual element time delay Class K5 fuses (20 amps if 240 volts 30 amp if 120) that will allow the motor to start

Then you need a flexible cord or flexible conduit running from the motor to the wall safety switch,,,,,,,,or a flex rubber cord from motor to wall mounted receptacle

SUMMARY

120 volt,,,,,,,,30 amp single pole 120 volt circuit breaker (40 if motor cant start without tripping breraker),,,,,,,,10 gauge wires,,,,,,,,120 volt 30 amp 3 prong receptacle and matching plug on the cord from motor,,,,,,,,or a wall mounted safety switch or fuzed safety switch with dual element time delay Class K5 30 amp fuse

240 volt,,,,,,,,,20 amp two pole 240 volt circuit breaker,,,,,,,12 gauge wires,,,,,,,,240 volt 20 amp 3 prong receptacle and matching 240 volt 20 amp plug on the cord from motor,,,,,,,or 240 volt two pole blade type safety switch or 240 volt two pole blade type fused safety switch with dual element time delay Class K5 fuses

GOT IT???????????????????

Hopefully the other fine gents can add to this for stuff I missed

John T