Bill Knecht

Member

Greetings, fellow Masseyphiles. I'm having trouble figuring out how to wire up the fuel level sensor to the fuel gauge on my 1971 MF135. Help would be most appreciated. Parts were purchased from Yesterday's Tractors.

The top picture shows the sensor with its two terminals, which I've labeled T1 and T2. There's a third, unlabeled screw with a metal strap on it that I assume is ground.

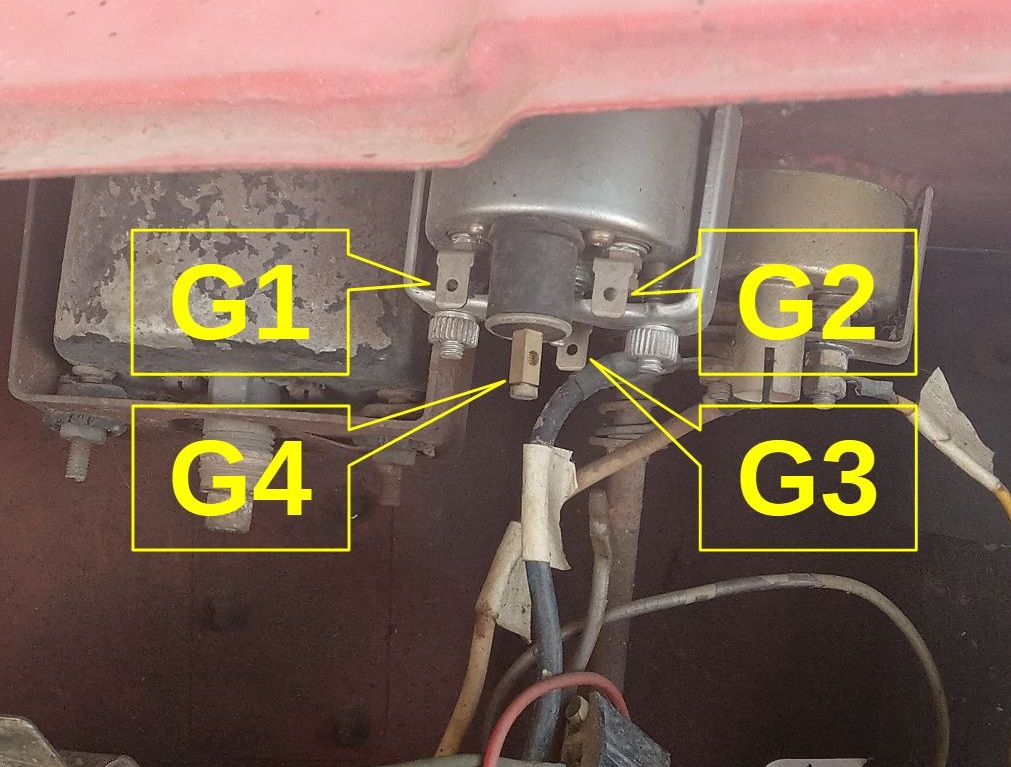

The bottom picture shows the gauge, which has no identifying labels on it. I assume terminal G4 is for lighting the gauge, which I don't care about. So, can anyone tell me "what connects to what" between sensor, gauge, battery, and ground? Normally, I'd experiment, but I don't want to blow anything out.

And, is there a way to calibrate the gauge to read accurately when empty and full?

Y'all rock. Many thanks!

The top picture shows the sensor with its two terminals, which I've labeled T1 and T2. There's a third, unlabeled screw with a metal strap on it that I assume is ground.

The bottom picture shows the gauge, which has no identifying labels on it. I assume terminal G4 is for lighting the gauge, which I don't care about. So, can anyone tell me "what connects to what" between sensor, gauge, battery, and ground? Normally, I'd experiment, but I don't want to blow anything out.

And, is there a way to calibrate the gauge to read accurately when empty and full?

Y'all rock. Many thanks!