Adirondack case guy

Well-known Member

I have been watching lots of U-Tube videos of current wood splitters. When I converted mine to 3pt hitch I had to build a block lifter to get the big blocks up onto the splitter bed which was then waist high. My solution was a gin pole with a 12V winch and grapple to lift them. Much cheaper and simpler than buying a 2 spool valve and doing all the plumbing for a lifting leg. It has served me well, but after watching the videos, I could also see advantages to the lifting leg on modern splitters as well. Not so much to lift the real heavy blocks, because the gin pole does that very efficiently, but to also use the leg as a tray to hold a number of smaller rounds that I can lift by hand, rather than running back and forth to grab another block each time I split one.

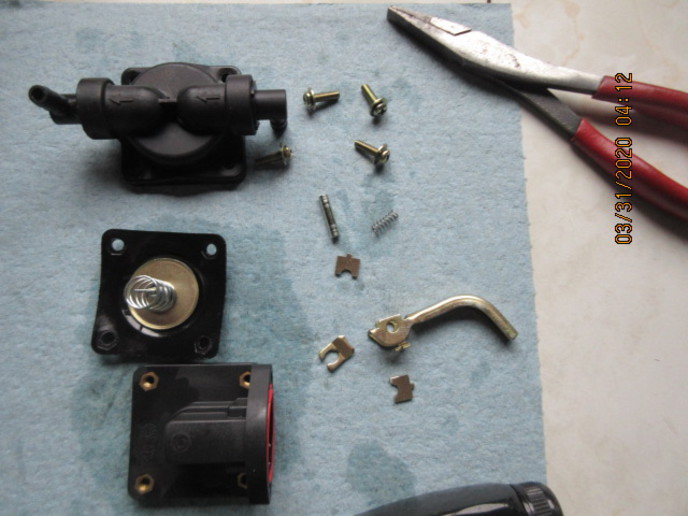

I built a telescoping leg, as the splitter can also be used setting down on it's wheels. The leg can also be switched from side to side by removing 2 pins. It can telescope out to 44" long at the heel of the forks, and retracted. to a length of 28". The gin pole still will do all the lifting, so still no need for a 2 spool valve, and I plumbed my hydraulic driven elevator so it only runs when the splitting cylinder is completely retracted and control lever is held back. One lever and the winch fob control the complete lifting, splitting and loading operation, and my back no longer suffers.

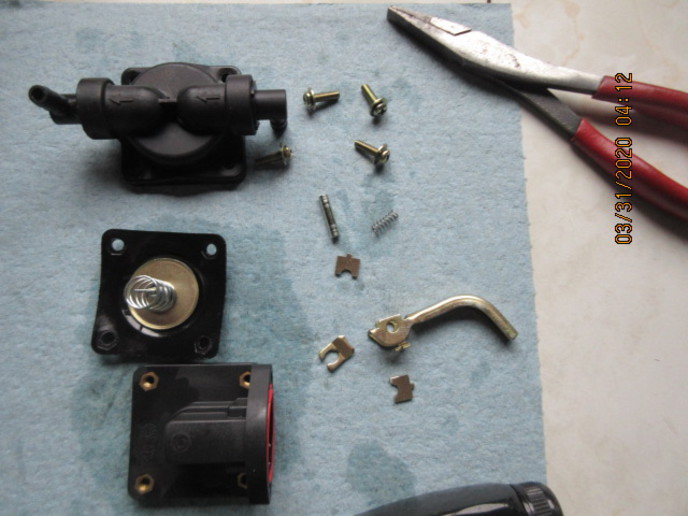

I also utilized a broken splitting maul handle that broke at the head to become a handle for a home fabed pickeroon. I built one several years back and it is a real handy tool, but it seamed that it was MIA back at the woodshed where I use it to grab blocks at the front of the trailers, when I needed it, so a second one was in order. This is what I formed out of a piece of 12G steel and the 25" long piece of the maul handle. The pickeroons alow me to grab and lift moderate sized blocks without bending over.

I also utilized a broken splitting maul handle that broke at the head to become a handle for a home fabed pickeroon. I built one several years back and it is a real handy tool, but it seamed that it was MIA back at the woodshed where I use it to grab blocks at the front of the trailers, when I needed it, so a second one was in order. This is what I formed out of a piece of 12G steel and the 25" long piece of the maul handle. The pickeroons alow me to grab and lift moderate sized blocks without bending over.

-----Loren

-----Loren

I built a telescoping leg, as the splitter can also be used setting down on it's wheels. The leg can also be switched from side to side by removing 2 pins. It can telescope out to 44" long at the heel of the forks, and retracted. to a length of 28". The gin pole still will do all the lifting, so still no need for a 2 spool valve, and I plumbed my hydraulic driven elevator so it only runs when the splitting cylinder is completely retracted and control lever is held back. One lever and the winch fob control the complete lifting, splitting and loading operation, and my back no longer suffers.