grandpa Love

Well-known Member

Last post was informative and entertaining

so here's more. Didn't fool with it on

Sunday, but had a few minutes Monday

afternoon. Removed the distributor and

governor. With only the 2 front rods

unbolted I can rock the tractor back and

forth in 4th gear. I can see the flywheel

moving a fair amount. I got to wondering

about my other parts B. Motor stuck, 2

cylinders have rust, 2 good and clean.

Block busted ( water jacket). Why can't I

push the 2 stuck pistons and sleeves out

of this one and the 2 good ones out of

that, and make one run? Use the same rods

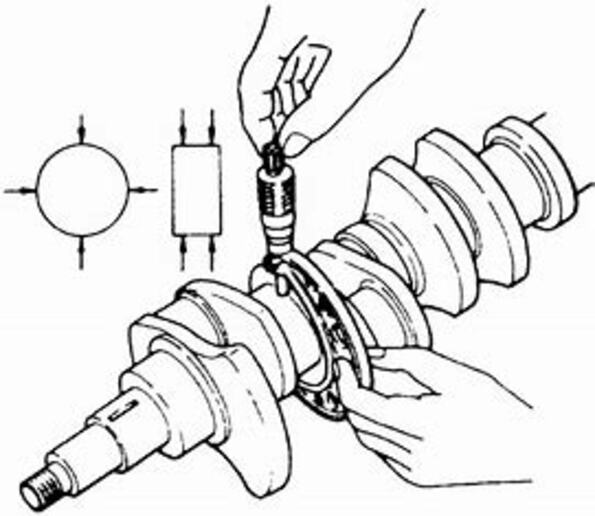

and bearings? I'm thinking I would need

new o rings? Thoughts?

so here's more. Didn't fool with it on

Sunday, but had a few minutes Monday

afternoon. Removed the distributor and

governor. With only the 2 front rods

unbolted I can rock the tractor back and

forth in 4th gear. I can see the flywheel

moving a fair amount. I got to wondering

about my other parts B. Motor stuck, 2

cylinders have rust, 2 good and clean.

Block busted ( water jacket). Why can't I

push the 2 stuck pistons and sleeves out

of this one and the 2 good ones out of

that, and make one run? Use the same rods

and bearings? I'm thinking I would need

new o rings? Thoughts?