Health challenges make it difficult to hook up my brush hog and rollover box blade. Basically don’t have as much heft and muscle as I did a few years ago. Thanks to Ultradog MN who sent some pictures of a flex-link lift arm, I began work on an “easier hitch” system for my Jubilee. Started with a couple of lift arms off of fleabay, that came off a Ford 4000 series. They don’t have the spring clip exchange ball, but I think the price was fair ($150 for the pair). They are 4” longer than the ones on my Jubilee. But, if I had gone with the Pat’s system it would have added 4” also. I’m hoping to use existing sway bars by moving them back on their bracket.

Tacked a Cat 1 bushing in the implement end ball. Can you tell I am no welder? Maybe it will hold. The bushing for the other end of the lift arm won’t have to be tacked because it is trapped when mounted on the tractor.

Had to rebuild one of the plunger pin thingys. New compression spring from a local hardware store, new cable made, and a pull ring cut from galvanized fence top rail piece. Silver color is anti-seize. Not sure how that will work, but going to give it a try.

New leveling box and side lift arm to accommodate the ¾” thick flex-link lift arms vs the ½” thick that are on the Jubilee now. They are also 2” longer to reach the lift point on the new lift arms. Had to bush the hole where they mount on flex-link arm. Grrrrr…wouldn’t go on the flex-link arms…fork not open enough. Took AWHILE to grind out enough metal to fit.

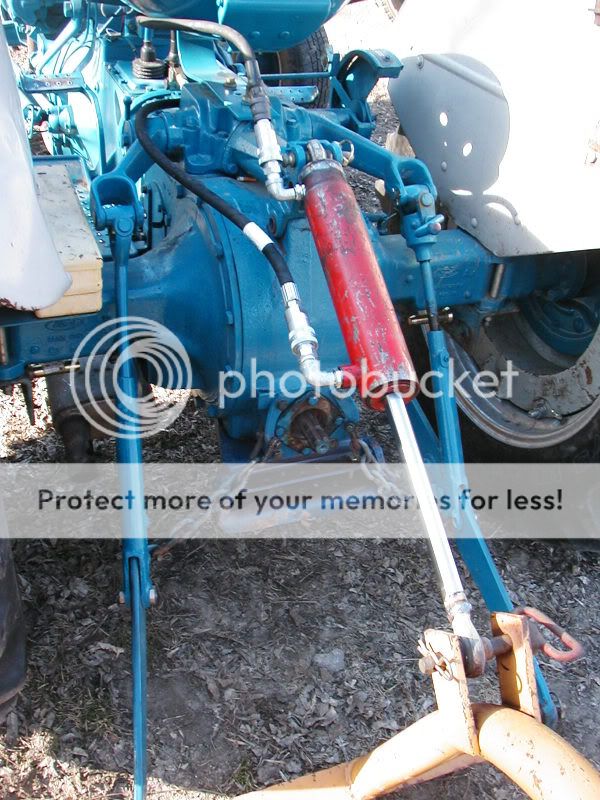

Test mounting on Jubilee. Need to get measurements to see what size top link I’m going to need. Looks like I need one that is a little longer to get full range. And, stabilizer arms need to be 2” longer, even if mounted in the back hole of the bracket.

Box blade is now MUCH easier to mount! No pry bar, no grunting! I’m sure I lost some lift capacity with the longer lift arms (I wonder how much), but think that is a fair trade off. I may need to lengthen the arms on the scoop and rollover blade so I can reach them easier. That shouldn’t be too difficult. Prep and paint planned when the weather is a little better. Thanks again to Ultradog MN for the idea!

Now on to the next idea…

Tacked a Cat 1 bushing in the implement end ball. Can you tell I am no welder? Maybe it will hold. The bushing for the other end of the lift arm won’t have to be tacked because it is trapped when mounted on the tractor.

Had to rebuild one of the plunger pin thingys. New compression spring from a local hardware store, new cable made, and a pull ring cut from galvanized fence top rail piece. Silver color is anti-seize. Not sure how that will work, but going to give it a try.

New leveling box and side lift arm to accommodate the ¾” thick flex-link lift arms vs the ½” thick that are on the Jubilee now. They are also 2” longer to reach the lift point on the new lift arms. Had to bush the hole where they mount on flex-link arm. Grrrrr…wouldn’t go on the flex-link arms…fork not open enough. Took AWHILE to grind out enough metal to fit.

Test mounting on Jubilee. Need to get measurements to see what size top link I’m going to need. Looks like I need one that is a little longer to get full range. And, stabilizer arms need to be 2” longer, even if mounted in the back hole of the bracket.

Box blade is now MUCH easier to mount! No pry bar, no grunting! I’m sure I lost some lift capacity with the longer lift arms (I wonder how much), but think that is a fair trade off. I may need to lengthen the arms on the scoop and rollover blade so I can reach them easier. That shouldn’t be too difficult. Prep and paint planned when the weather is a little better. Thanks again to Ultradog MN for the idea!

Now on to the next idea…