There are people of all walks of life on here, are there any dry wallers?

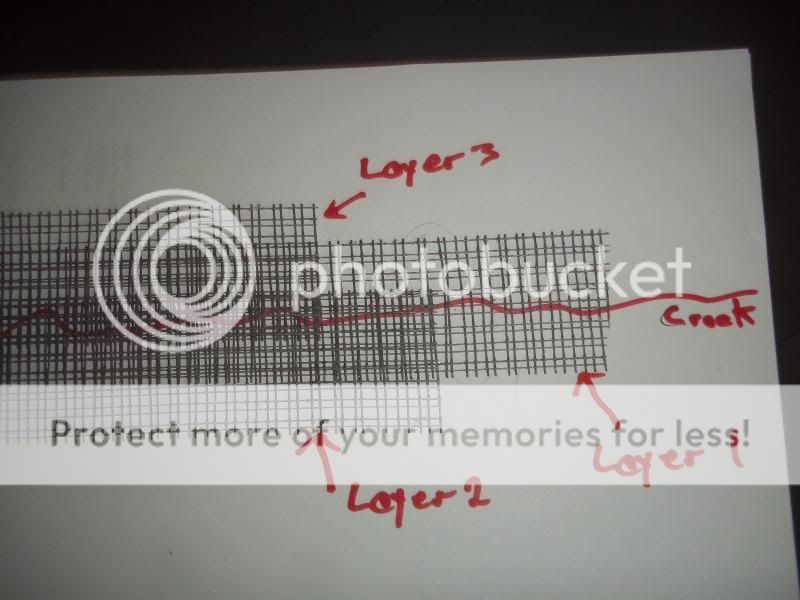

My son just bought a house with a vaulted ceiling over the kitchen, dining and living room. The entire area is sheet rocked. Above the top plate in about the middle of the vault on both the exterior and interior walls there is a vertical crack. I was told you can fix it but it will crack again because that is where two pieces of sheet rock meet. On both cracks there is a door way corner at the edge of the crack.

Was I told BS or can you just tape it then mud it and be done. Or is there a better way?

My son just bought a house with a vaulted ceiling over the kitchen, dining and living room. The entire area is sheet rocked. Above the top plate in about the middle of the vault on both the exterior and interior walls there is a vertical crack. I was told you can fix it but it will crack again because that is where two pieces of sheet rock meet. On both cracks there is a door way corner at the edge of the crack.

Was I told BS or can you just tape it then mud it and be done. Or is there a better way?