Great cut-away , thx!

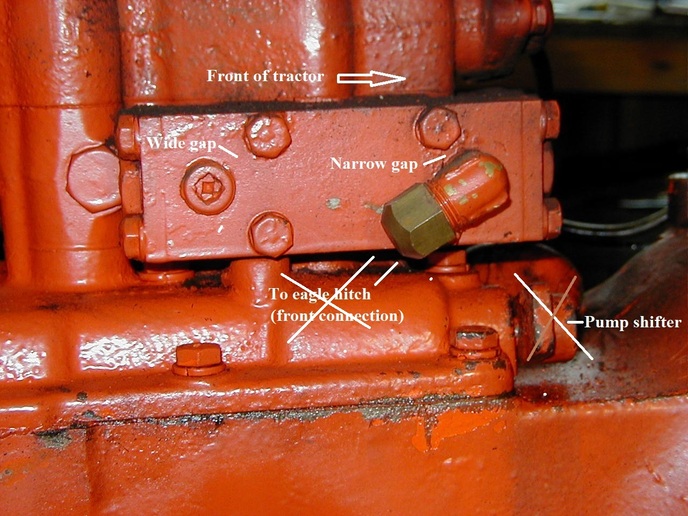

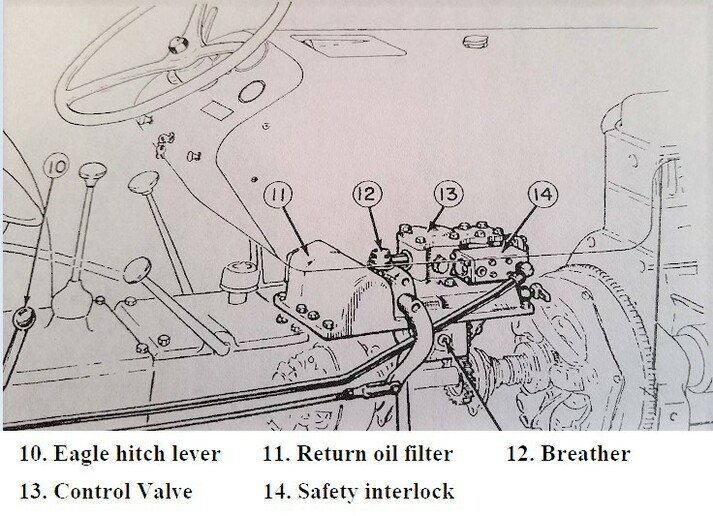

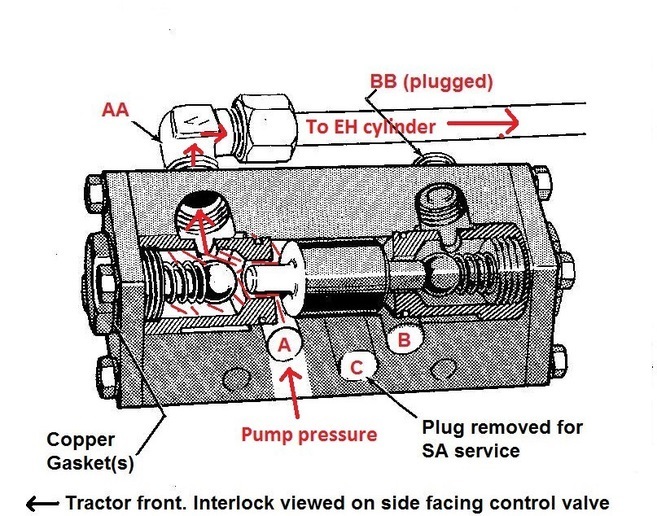

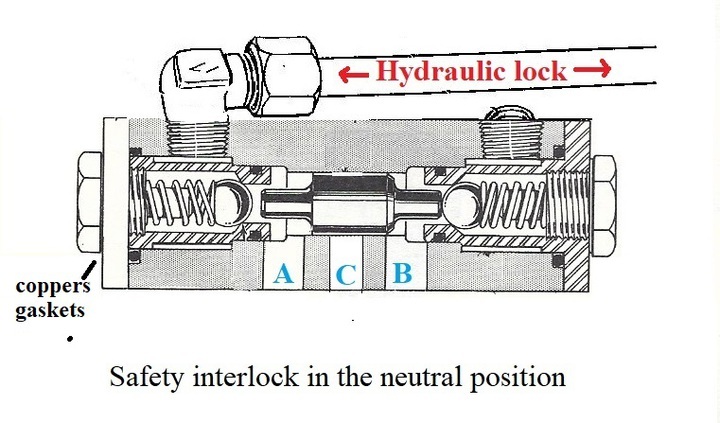

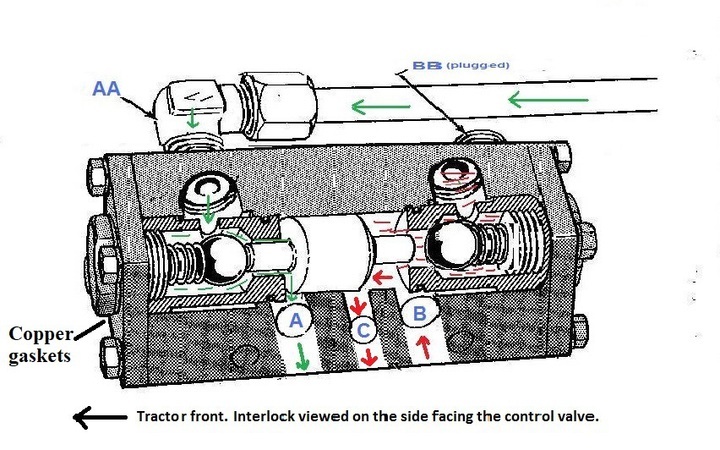

Tricky to get straight on like yours, but here's two pics to make one side view of my PC interlock.

Also, I tried scanning a schematic drawing I did earlier for the existing hydraulic layout on this tractor. Does it make sense? It supports your idea of eliminating the complete LC valve and TT dump while going directly through the SC to either the loader rams or the EH. and just to use the seat lever to operate one or the other. I guess I could live with that as an operational setup to get the tractor functioning. It should sell like that, if the only solution? Perhaps adjustment will be straight forward as I get a chance to tinker? Seems to me there is a couple of "stops" to adjust and some bent rods?

Are you seeing anything better?