jimmybeam01

Member

So had tractor running and all of a sudden she shut down. I changed the key switch. Checked everything. So before I changed the key switch I had constant 12 volts to the coil coming out of the coil and through the points. Changed key switch and with the test light at the wire post on the side of the dizzy when I hit the key the light blinks like its in sync with timing. So my question is. Wtf

Is it supposed to be solid 12 volts to the dizzy or intermittent through coil and all. But whats even weirder is when Im laying on the key through complete frustration which is wrong of me.. it will pop once. Like it catches power at the right moment. But even with 12volts solid to the dizzy it does the same thing!

So tell me. Whats the proper wiring. Whats the prob. I got juice to the points and the little capacitor, Im drawing a blank on the name of it right now. Snows coming! I need this turd!

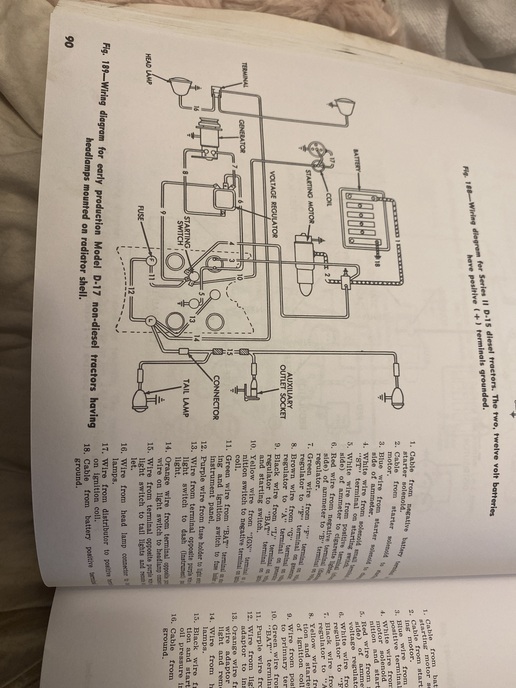

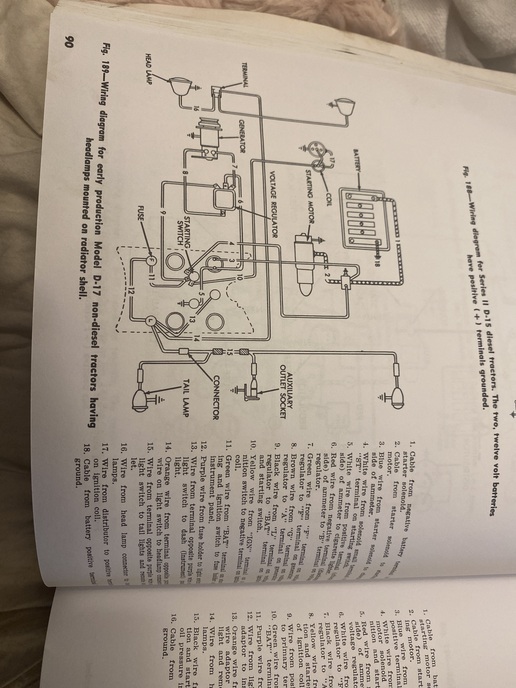

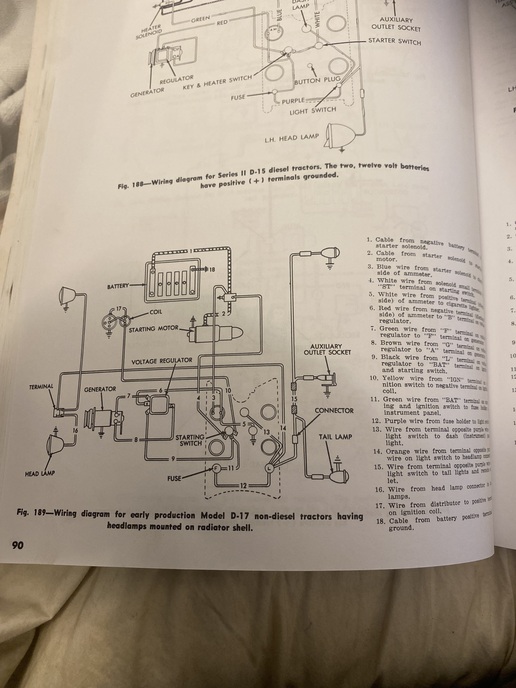

Thanks for help and guidance l. I do got the IT shop manual that covers d17 but I dont care so much for this book. Would like a original shop manual..

Is it supposed to be solid 12 volts to the dizzy or intermittent through coil and all. But whats even weirder is when Im laying on the key through complete frustration which is wrong of me.. it will pop once. Like it catches power at the right moment. But even with 12volts solid to the dizzy it does the same thing!

So tell me. Whats the proper wiring. Whats the prob. I got juice to the points and the little capacitor, Im drawing a blank on the name of it right now. Snows coming! I need this turd!

Thanks for help and guidance l. I do got the IT shop manual that covers d17 but I dont care so much for this book. Would like a original shop manual..