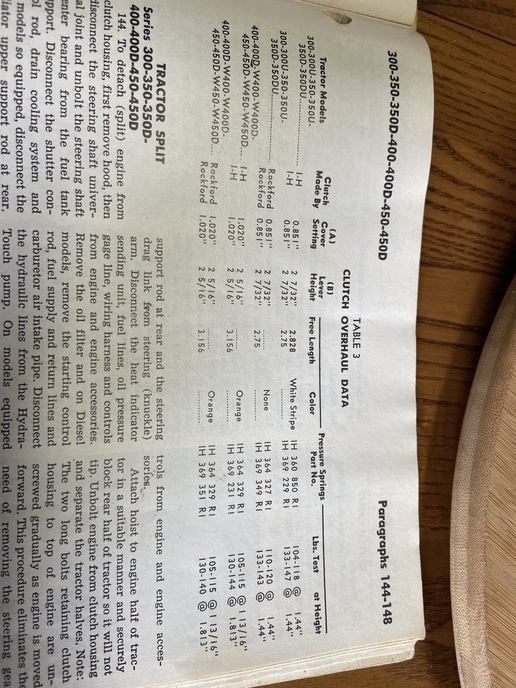

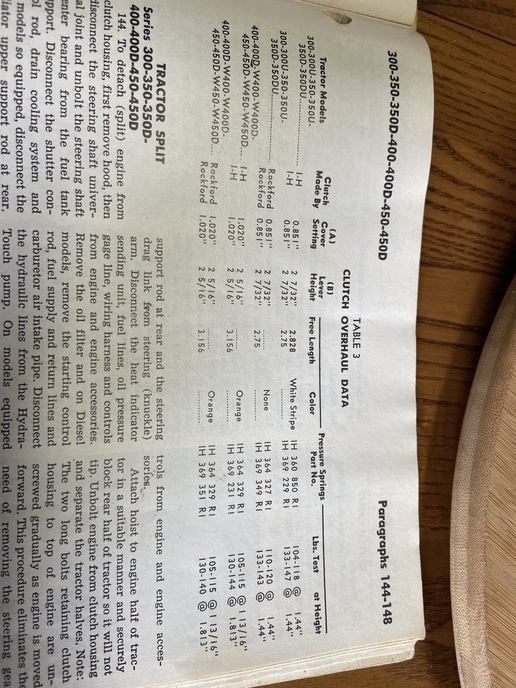

New pressure plate for my 300U measures 1.940 between top of finger and the lowest surface of the cover plate. (Photo #1) Between the top side of friction surface and highest point of the underside of the cover plate is 0.965. (Photo #3) According the the manual I want them to read 2.219 and 0.851 respectively. Assuming I am measuring from the correct surfaces. I understand how to adjust the fingers, but I am not sure how best to go about adjusting everything. I am assuming that these numbers are taken on the bench, and not after being bolted onto the flywheel with the friction disk in place. Any help would be appreciated.

Thanks in advance!

Thanks in advance!