tracto-man

Member

Maybe a little OT, but trucks are tool and we use tools to work on them right?

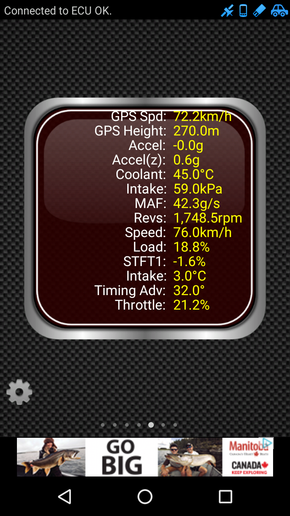

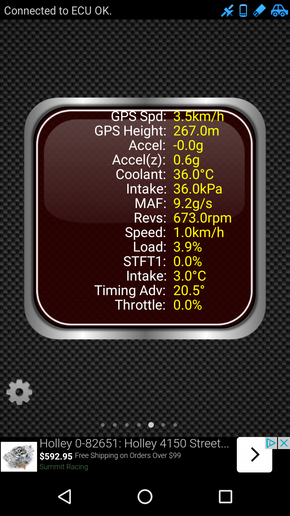

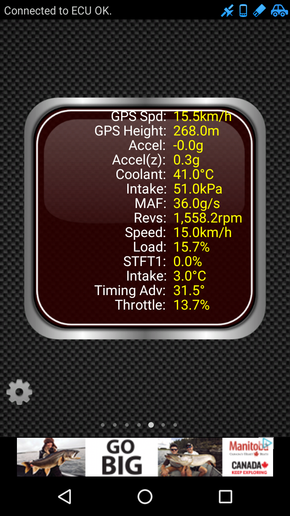

A friend and myself got to messing around with this 1998 Chevy K1500 5.7 350 4x4 pickup. It runs okay but if floored or right about 2500 rpms it will bog out and back fire. Runs really ruff and will about die unless let off the gas and don't go above 2500 rpms. Seems a clogged exhaust so we unbolted that to rule out that problem, put some new plugs cap and rotor in, tested the egr Valve which tested good, cleaned the throttle body, still same issue. Tested mass air flow sensor and a few others as well, map sensor etc, all testing good.

Kinda at a loss now. No check engine light either. Maybe just time to tell the guy take it to a real mechanic? I hate giving up on stuff, lol

A friend and myself got to messing around with this 1998 Chevy K1500 5.7 350 4x4 pickup. It runs okay but if floored or right about 2500 rpms it will bog out and back fire. Runs really ruff and will about die unless let off the gas and don't go above 2500 rpms. Seems a clogged exhaust so we unbolted that to rule out that problem, put some new plugs cap and rotor in, tested the egr Valve which tested good, cleaned the throttle body, still same issue. Tested mass air flow sensor and a few others as well, map sensor etc, all testing good.

Kinda at a loss now. No check engine light either. Maybe just time to tell the guy take it to a real mechanic? I hate giving up on stuff, lol