I took your advice and took the primer pump apart. Sure enough there was crud in the primer pump restricting the flow. As also suggested, I also found an aftermarket plunger asm. Engine is running good again but the saga continues. Have a cup of coffee and put a log on the fire----or go help mama cook the turkey. LOL

Typically when the engine is not completely warmed up, I pick a lower gear and work part throttle for a few minutes so I plowed about a half mile in 3rd. They it slipped out of 3rd gear with a LOUD BANG. There were no additional bad sounds. All was quiet except the engine racing but the loud bang was one of those no more plowing this year noises.

I looked at the shift lever and it was still in 3rd position. That seemed strange for slipping out of 3rd. I moved the lever back to neutral and then back into 3rd. 3rd gear had become totally disconnected from the lever in the cab. I pulled the lever back into 4th which felt normal and the tractor would move. I eased back to the barn in 4th without any proverbial monkey wrench in the gears noises or clunking.

Back in the barn, I easily moved the shift lever out of 4th back to neutral but letting the clutch partially out inched the tractor forward. Putting the lever in 3rd position, the tractor would now also inch forward. That seemed strange.

1st, 2nd, and reverse shifted normal except the transmission was locked when put in each of those three gear positions. After a little head scratching, I figured that the transmission must have stayed in 4th and was probably locking in two gears.

YUP the shift lever was totally disconnected and freely moved completely in the 3rd 4th slot.

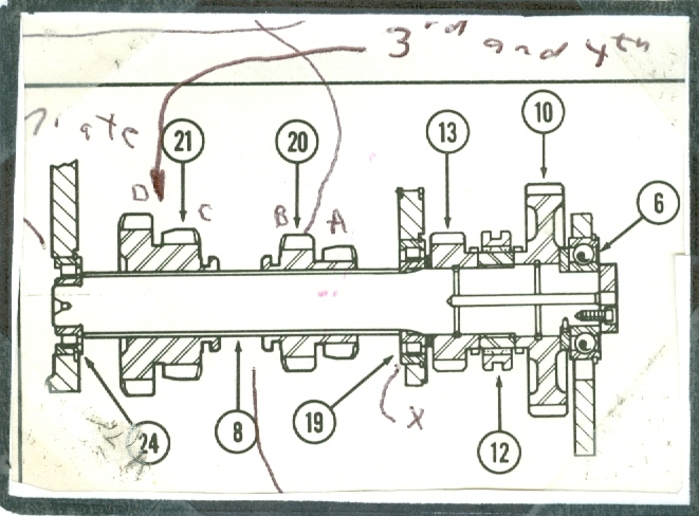

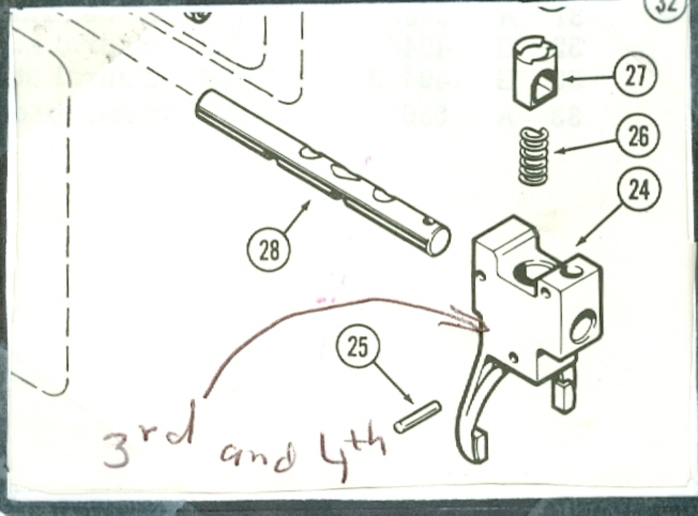

Here are pictures of the mechanism that I think probably contains the malfunction. The shifter fork contains a square cornered locking detent for each gear. I haven't opened the inspection hole yet but I am suspecting that the shifter fork is split and the locking detent may be still locked.

My repair manual shows the power shift has similar range shift hardware. Have any of you had this same problem with the 70 series?

I am puzzled why 3rd gear under load might apply a breaking force against the shifter fork. I suspect the first owner may have pulled a bigger plow and ran a lot of hours in 3rd for much of its first 2500 hours. The gear might be worn. I havent had much need to use 3rd a lot. The fix will likely be time consuming. I know the cab has to come off in order to remove the top cover.

I have gotten too old. The junkman should be held at bay. A lot of the tractor is still good.

Happy Thanksgiving Day.