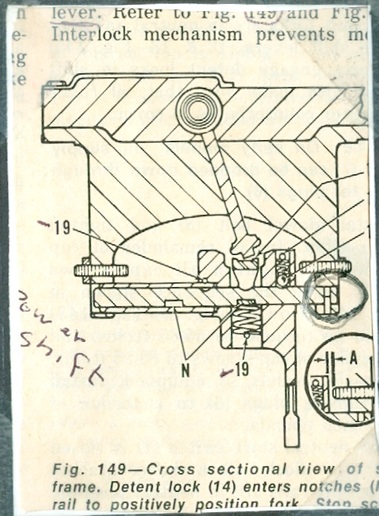

Apparently in low range, 3rd gear, under high load, slipped free of the fork and rapidly slid toward 4th causing a split second but very hard gear grind to occur. I interpreted this sounding like a loud bang.

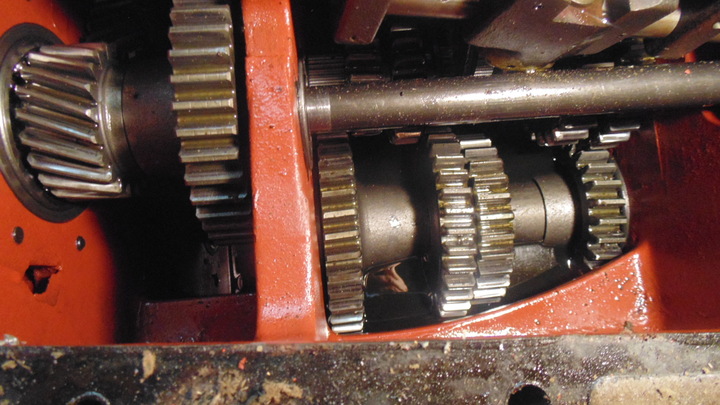

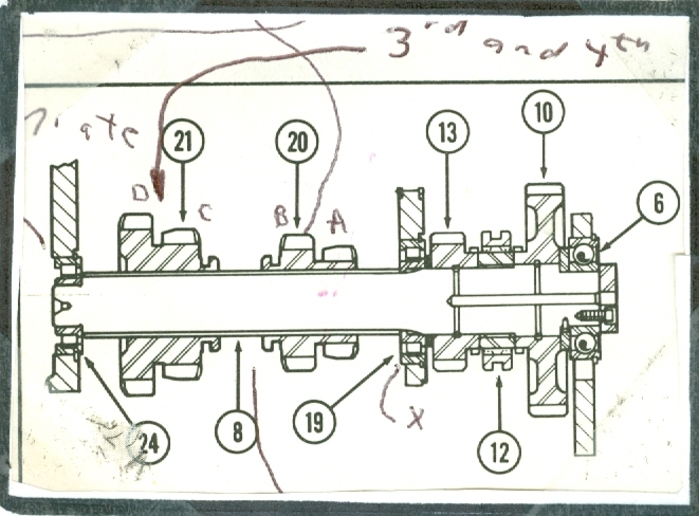

The first pictures show the driven gears with low range 3rd and 4th on the right. The second picture shows these drive gears are a cluster--- having the weight of a hefty hammer.

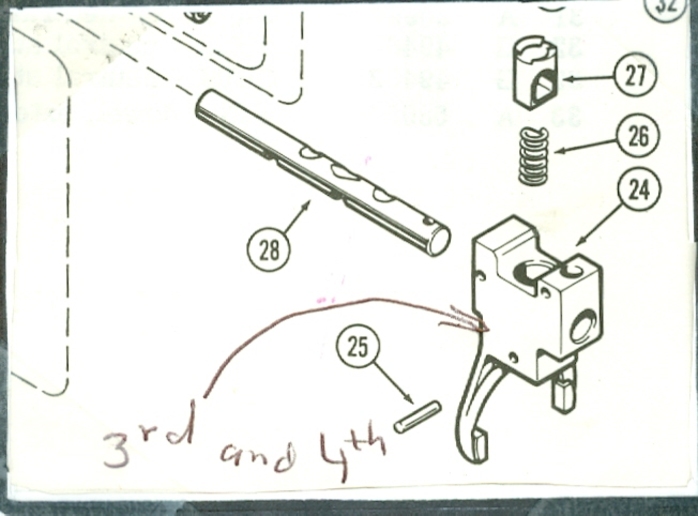

Comparing the two forks that hold the two slideable drive cluster gears, the groove-engaging tabs are missing off the 3rd - 4th -7th -8th fork seen closer up. I measured the gear groove's flange which measured 3.013 inches. I had a 3-inch OD washer which fit nicely in the damaged fork. Apparently, the fork's tabs had experienced rapid wear rather than an overload break.