I see other Balers continuing to operate while turning online.

I am trying to bale enough to feed a few rescue horses, I cut and bale on small properties 3 acres or less. what used to be a what used to be a hay field is now a subdivision. The landowners allow me to make use of the grass they grow on their properties instead of paying someone to brush hog. Pretty good deal for both of us. This makes for many short runs with many turns.

So, why do I hear a lot of banging and clanging while making turns. I understand that this would put stress on the U-joints. is there a modification that would make baleing around terms possible?

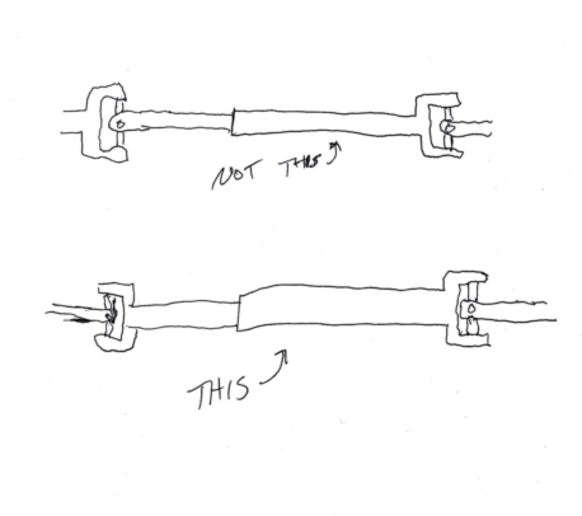

-A thought that I had was to weld the support between the front and back half of the driveshaft in a vertical position and level with the tractor. The Junction between the front and back driveshaft would still be able to Swivel right and left, and the front portion could be replaced with a sliding/extending drive pto shaft.

or is something else causing the banging and clanging on turns?

another piece of information is that it very occasionally (actually the only time it breaks a shear pin) breaks and shear pin when the PTO is shifted into neutral.

I am trying to bale enough to feed a few rescue horses, I cut and bale on small properties 3 acres or less. what used to be a what used to be a hay field is now a subdivision. The landowners allow me to make use of the grass they grow on their properties instead of paying someone to brush hog. Pretty good deal for both of us. This makes for many short runs with many turns.

So, why do I hear a lot of banging and clanging while making turns. I understand that this would put stress on the U-joints. is there a modification that would make baleing around terms possible?

-A thought that I had was to weld the support between the front and back half of the driveshaft in a vertical position and level with the tractor. The Junction between the front and back driveshaft would still be able to Swivel right and left, and the front portion could be replaced with a sliding/extending drive pto shaft.

or is something else causing the banging and clanging on turns?

another piece of information is that it very occasionally (actually the only time it breaks a shear pin) breaks and shear pin when the PTO is shifted into neutral.