johndeeregreg

Member

just bought the tractor with some transmission issues so got it in and tore transmission down, both sides apart flywheel, timing cover, clutch,

pulley, first reduction cover, ect. put it together and now it seems to have a knock that i don't remember it having before working on it. few

things to note

-endplay is at .009 (early style that uses shims to set endplay)

-clutch could use some work floating disks are rather loose on the driver splines and the 3 pins that the friction disks on plate go on are grooved

pretty good.

-knock seems to be worse with clutch disengaged

-tried it with all clutch parts out accept the driver and friction disk behind it

-checked injection pump timing but timing marks on pumps are off or something, if adjusted to line up on flywheel injection mark it pushes plunger

to far and cant roll engine over. as they are now the pump marks line up with flywheel mark on tdc, comparing location of mark with pump on my other

720 at same flywheel position the plunger marks seem to be in the same area in timing window. and it starts right up so i don't think it is timing

issue

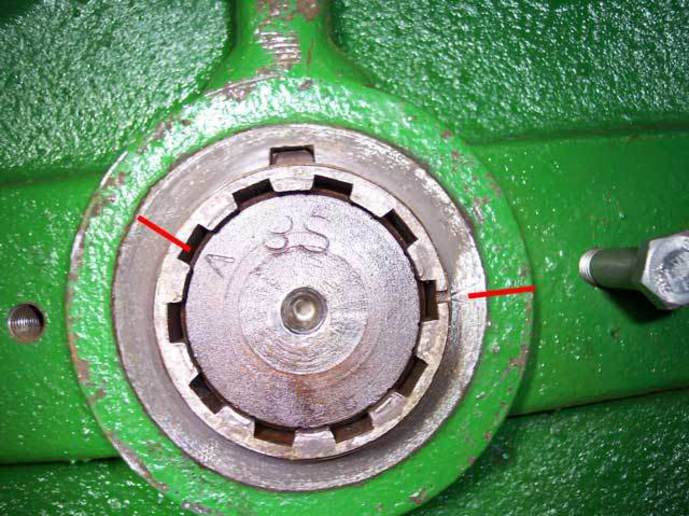

-with flywheel bolts at 275 lbs i removed the tin nut and was able to rock flywheel back and forth a little on crank (forward and backward not side

to side), tightened flywheel bolts to 325 lbs and that seemed to eliminate being able to rock flywheel by hand.

what am i missing? or need to check?

pulley, first reduction cover, ect. put it together and now it seems to have a knock that i don't remember it having before working on it. few

things to note

-endplay is at .009 (early style that uses shims to set endplay)

-clutch could use some work floating disks are rather loose on the driver splines and the 3 pins that the friction disks on plate go on are grooved

pretty good.

-knock seems to be worse with clutch disengaged

-tried it with all clutch parts out accept the driver and friction disk behind it

-checked injection pump timing but timing marks on pumps are off or something, if adjusted to line up on flywheel injection mark it pushes plunger

to far and cant roll engine over. as they are now the pump marks line up with flywheel mark on tdc, comparing location of mark with pump on my other

720 at same flywheel position the plunger marks seem to be in the same area in timing window. and it starts right up so i don't think it is timing

issue

-with flywheel bolts at 275 lbs i removed the tin nut and was able to rock flywheel back and forth a little on crank (forward and backward not side

to side), tightened flywheel bolts to 325 lbs and that seemed to eliminate being able to rock flywheel by hand.

what am i missing? or need to check?