Hi all,

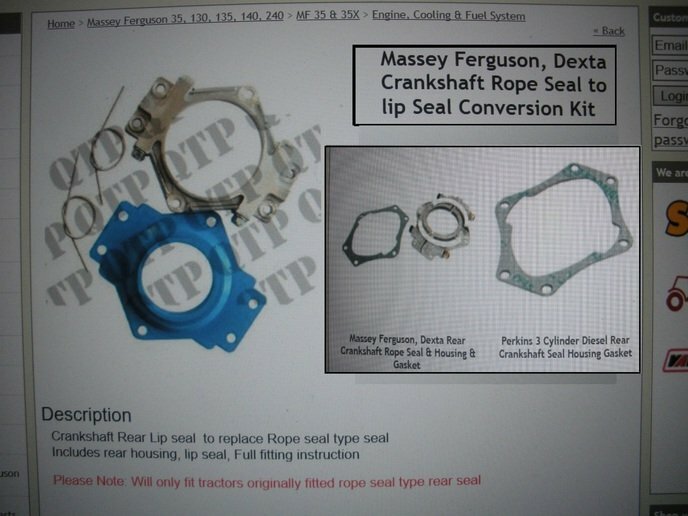

I'm wrapping up the bottom end of my AD3.152 rebuild (from a MF2244 crawler) and I'm to the point of doing the rope seals. Seems like the best I can ever do with a rope seal, I still end up with leaking. I spend quite a bit of time fabricating and machining, and was trying to figure out a good way of adapting a different seal onto mine when I ran across something someone else already created:

https://www.youtube.com/watch?v=zxBqGHQ10J8

https://www.ebay.com/itm/263894940033

Has anyone tried one of these yet? It looks like a pretty decent kit, my only concern is whether they used a polymer that is compatible with the environment of a rear main seal.

Any thoughts?

I'm wrapping up the bottom end of my AD3.152 rebuild (from a MF2244 crawler) and I'm to the point of doing the rope seals. Seems like the best I can ever do with a rope seal, I still end up with leaking. I spend quite a bit of time fabricating and machining, and was trying to figure out a good way of adapting a different seal onto mine when I ran across something someone else already created:

https://www.youtube.com/watch?v=zxBqGHQ10J8

https://www.ebay.com/itm/263894940033

Has anyone tried one of these yet? It looks like a pretty decent kit, my only concern is whether they used a polymer that is compatible with the environment of a rear main seal.

Any thoughts?